#Textiles & Apparel / Garment

YKK unveils innovative zipper to boost garment recycling

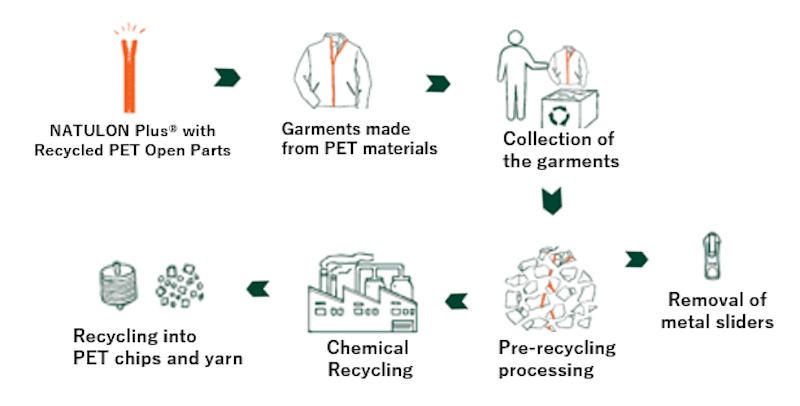

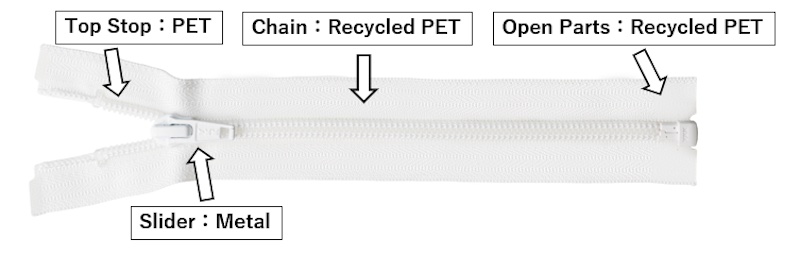

In the fashion industry there is an increasing demand for products that are designed to be easily recyclable at the end of their lifecycle. YKK is pleased to announce the new NATULON Plus® with Recycled PET Open Parts, a zipper maximizing the use of PET materials, which was conceived as a more easily recyclable YKK® product. The chain and the open parts are made of recycled PET, and the PET materials for the injection molding of the open parts were developed by YKK in-house. The slider is made of metal for ease of sorting and durability. This product simplifies the garment processing stage of textile recycling by reducing the need to remove the zipper.

Product Introduction: NATULON Plus® with Recycled PET Open Parts

Terry Tsukumo, Vice President, Product Strategy Division, Global Sales Headquarters, YKK Corporation, comments:“A large amount of apparel products is thrown away each year. We need to extend the service life of products while simultaneously designing them to be easily recyclable after use. We believe that incorporating YKK’s NATULON Plus® with recycled PET open parts into garments will simplify the garment processing stage and enable more of them to be recycled along with the garments. YKK has previously developed products that help to enable a circular economy such as VISLON® NATULON® made with ECONYL® Regenerated Nylon, a recyclable product which is intended for nylon garments, as well as revived replacement elements for VISLON® zippers which can replace broken elements to keep garments functioning longer. YKK will continue enhancing its products designed for circularity such as those that are easily recyclable and repairable, while aggressively working to tackle environmental problems in the apparel industry across the entire supply chain.”

Other products that aim to bring about a circular economy

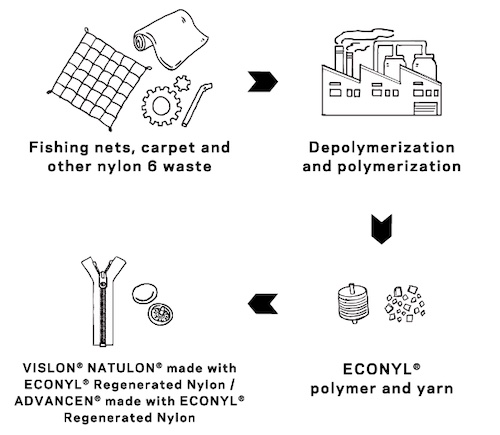

+ VISLON® NATULON® made with ECONYL® Regenerated Nylon

Made of ECONYL® regenerated nylon, this zipper for nylon garments has been developed so that it can be recycled back into raw materials after use.

+ ADVANCEN® Made with ECONYL® Regenerated Nylon

This snap button is made of a single plastic material, using more than 98% recycled nylon ECONYL®.

+ Revived Replacement Elements for VISLON® zippers

This allows users to replace only the damaged element, without replacing the entire zipper.

+ DynaPel®

This zipper features a water-repellent function that does not rely on polyurethane (PU) films or coatings, which are often incompatible with many recycling systems.

+ TouchLink®

The zipper slider is equipped with an NFC chip, allowing customers and recyclers to easily access detailed information about the product with TouchLink® technology. This includes production date and location, material composition, care instructions, repair information, and more.