#Textiles & Apparel / Garment

Toray develops Qticle™, a smooth and supple new fabric

The company will offer Qticle™ for everything from casual medium-weight fabrics for men’s and ladies’ outerwear through cut-and-sewn items, broadening the design freedom and potential for high-end apparel in Japan and around the globe. Toray aims to commercialize this fabric for spring/summer 2023 collections. It targets annual sales of 200,000 meters in fiscal 2022 (through end-March 2023), and 500,000 meters by 2025.

Hair and wool comprise numerous protein layers. Their properties and structure deliver excellent elastic-ity and luster.

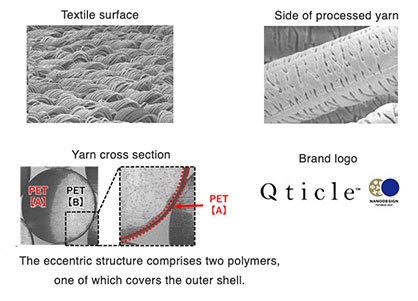

Qticle™ is a biomimetic fabric. Toray created it by em-ploying its proprietary NANODESIGN™ composite spinning technology to design an eccentric yarn with an ultrathin shell layer with which it combined fiber processing technology to create a crimped structure and fine surface irregularities. An eccentric yarn has a cross-section with two different pol-ymers, each with different centers of gravity.

Toray’s technologies have enabled it to attain natural, lustrous, and deep colors, a pleas-antly smooth and supple feel, and functional stretch for comfort and easy care.

In the years ahead, Toray looks to also offer a range with polymers made from recycled materials to cater to sustainability needs.

The COVID-19 pandemic accentuated the need for fashion to learn from and respect nature, as ethical consumption and veganism do, rather than seeking to control and exploit.

Toray will continue to explore new possibilities for fashion through research and technolog-ical development that scientifically recreates the attributes of natural materials.

The company will continue to cater to and help enhance diversifying lifestyles by supplying innovative technologies and advanced materials.

Qticle™ overview

1. Features

(1) Natural, glossy, with deep coloration.

(2) Smooth, supple texture

(3) Stretchy for comfort and easy care

(4) Functional chemicals deliver exceptional performance and durability

2. Technologies

(1) Eccentric yarn with ultrathin shell layer incorporates NANODESIGNTM composite spinning technology

(2) Special yarn treatment for random thickness and crimp structure along fiber

(3) Ultrathin shell of fiber specially treated to form fine irregularities on surface

3. Launch timing: For spring/summer 2023 collections

4. Sales targets

(1) Volume: 200,000 meters in fiscal 2022 and 500,000 meters by 2025

(2) Applications: Including men’s and women’s outerwear, shirts, blouses, and cut-and-sewn garments