#Yarn & Fiber

Teijin Frontier unveils new extra-absorbent, fast-drying fabric with diatomaceous earth-like surface

About the new fabric:

- Technology

Similar to diatomaceous earth

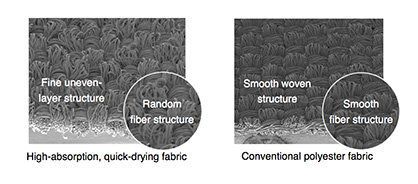

- Composite yarn is processed to swell as longitudinal warp and expand and contract as transverse weft, realizing a fabric surface with a fine uneven structure.

- The microporous surface structure, replicated by imitating diatomaceous earth creates interthread voids within a woven structure, using varying shrinkage in composite yarn to form convex parts.

Natural fiber-like structure

- Natural-like appearance of fabric surface created with composite yarn made comprising random fibers of varying fineness and shrinkage.

- Structure

While conventional polyester fabrics have a smooth woven structure made with uniformfibers, the new fabric has a fine uneven structure made with random fibers.

- Fabric Features

The new fabric offers excellent waterabsorption and diffusion for quick drying. It also achieves a natural-like appearance and is stretchable.

High absorption andquick drying

Fabric instantly diffuses moisture, is highly absorbent and dries some 40% faster than ordinary polyester thanks to density difference of uneven layer structure, which has a diatomaceous earth-like surface and a convex part that promotes capillary action.

Washing durability

Excellent durability even after 50 washings to maintain fabric structure’s water-absorptionandquick-drying properties.

Natural-like look and texture, plus stretchability

Natural-like achieved with composite yarn made with random fibers of varying shrinkage. Yarn expands and contractsfor moderate stretchability and soft texture. Wrinkles less than ordinary polyester.

Due to increases in double-income and single-person households, demands are rising for products that help to minimize housework, such as washing clothes. Related to this trend is the increasing popularity of easy-care attire that dries quickly after washing. Furthermore, clothing with natural-like appearances and textures have come into vogue in recent years.