#Texprocess 2015

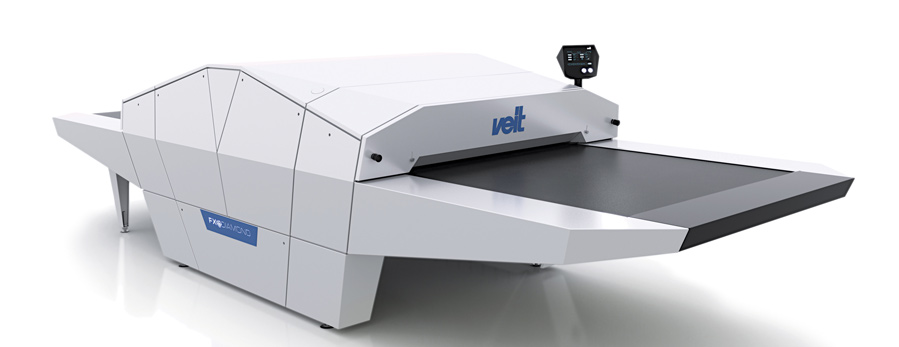

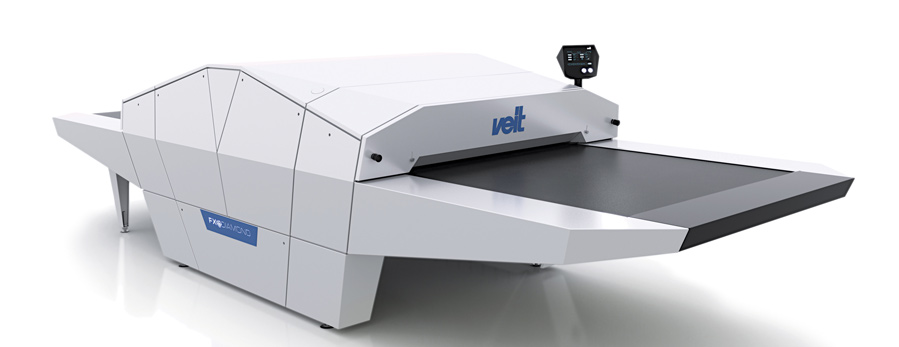

Texprocess Innovation Award 2015 goes to VEIT Fusing 4.0

Artificial intelligence (AI) rapidly transforms the textile industry - from creation and production to pricing, distribution and communication. But how can AI be applied successfully, and where does it truly add value? Heimtextil addresses these questions from 13 to 16 January 2026: The comprehensive programme dedicated to the key future field AI strengthens the global industry and opens up new business opportunities as well as practical applications for design, retail, industry, architecture, interior design and contract furnishing.

After more than ten successful years at Lindauer DORNIER GmbH, Mr Wolfgang Schöffl will leave the family-owned company at the end of the year to enter well-deserved retirement.

Under the banner 'Texpertise Focus AI, Messe Frankfurt will place a strong emphasis on Artificial Intelligence (AI) across its international textile and apparel trade fairs from 2026 onwards, setting a future-shaping signal for the industry. The initiative highlights the responsible use of AI along the entire textile value chain, from fibre production to the point of sale. The programme will launch at Heimtextil in Frankfurt in January 2026.

As the global market leader in sustainable acoustic and thermal management, Autoneum is a key supplier of interior and exterior components for the highly anticipated Polestar 5 model. The successful collaboration between Autoneum and Polestar marks a significant milestone in sustainable automotive engineering: the electric grand tourer sports car features several innovations in lightweight, fully recyclable polyester-based components that ensure a superior driving experience. Polestar 5 was revealed at the IAA Mobility 2025 in Munich and is available in 24 markets.