#Texprocess 2015

VEIT Group is setting new standards at Texprocess 2015

Among the wide range of high-end products are the BRISAY SC / VC Series, a new generation of pressing machines to achieve excellent quality and high efficiency while at the same time allowing easy, comfortable handling.

Another new product at the show is the FX Diamond 1400, the latest machine from the FX Fusing Machine series. VEIT engineers have optimised the famous Kannegiesser technology to reach a completely new level of fusing quality.

„Innovation, precision and quality is what we stand for“, Group CEO Günter Veit emphasizes. „Our customers‘ needs are always at the focus of our attention. For their benefit, we design module-based units, customized production lines and innovative services.”

VEIT now offers a brand-new service which is unique in the industry: the Pay Per Piece service for Shirt Finisher VEIT 8326. Instead of buying the machine, customers pay only for how much they actually use it.

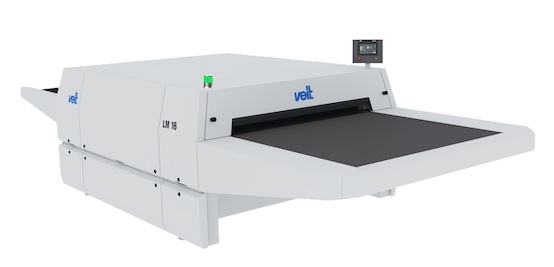

Yet another result of the Group’s eagerness to offer innovative engineering solutions are the new FX CFL Laminating Machines for gentle fusing and laminating of flexible materials such as leather and textile cuttings of any composition. These machines can be extended to build a complete production line by adding long loading systems, cooling modules and stacking devices.

VEIT Group, based in Landsberg am Lech (Germany), is the world’s leading manufacturer of machines and equipment for ironing, fusing, pressing and refinishing of garments. Its product range includes everything from traditional ironing tables and presses to fusing machines and highly automated systems such as tunnel finishers and bagging machines.

For almost 60 years, VEIT Group products have been the epitome of outstanding quality and highest productivity. This is why garment manufacturers as well as garment refinishers, logistics companies and customers from the automotive industry rely on VEIT technology. With numerous subsidiaries and an excellent distributor network around the world, VEIT Group continues to grow globally.