#Techtextil 2022

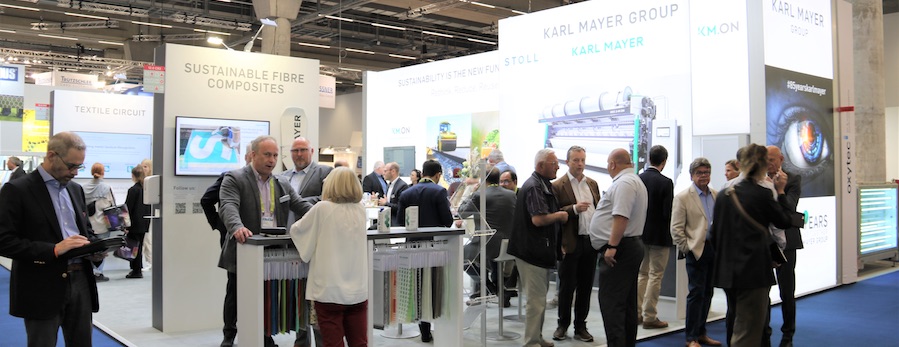

Many visitors and in-depth conversations - Successful Techtextil for the KARL MAYER Group

Most of the guests came from Germany and from the neighboring countries of Switzerland and Austria. Important visitor nations were also India, Turkey, the USA, Italy, Portugal and Korea.

The atmosphere on the KARL MAYER stand was exceptionally good. "The trade visitors were very interested and were looking forward to the exchange after the long Corona break," said Jochen Schmidt. The President of KARL MAYER Technische Textilien and his team held intensive technical discussions about textile solutions for relevant challenges of our time. Topics included sustainable composites made from natural fibers - a snowboard was exhibited for this purpose - and textile products for water treatment, e.g. by filtration or seawater desalination, but also about textiles for higher-quality and more sustainable construction. Here, warp knitted fabrics with weft insertion have already become firmly established.

There was also great interest in solutions from the world of new technologies: in a warp knitted fabric with directly integrated electrically conductive material that can be used for gesture control, and in a sports shirt with 3D printing. The 3D printing process can be integrated inline into series production.

The STOLL team also had their hands full at the KARL MAYER stand. Many existing customers, particularly from the medical, shoe and automotive sectors, had come to find out about the latest flat knitting innovations. In addition, curious visitors looking for new business fields as well as sportswear and fashion brands had a wide range of questions. They all found what they were looking for. STOLL had a wide range of technical knitwear in its trade fair luggage, including form-knitted seat covers, innovative articles for bandage technology and the latest shoe uppers that meet 100% of the required sustainability expectations.