#Techtextil 2019

Sustainable and functional solutions for textiles

One of the highlights this time is breathable yet waterproof outdoor clothing. It is intended to protect joggers or hikers from rain, but at the same time let sweat escape from their skin. With the INSQIN® technology, textiles are coated with waterbased polyurethane (PU) dispersions without the use of solvents.

The breathable textiles impart a pleasantly comfortable feeling. This is ensured by an adhesive coating based on Impraperm® DL 5310 dispersion and a top coat based on Impraperm® DL 5249. Both products also give backpacks, shoes and gloves their desired functionality.

Biodegradable textile coating

When assessing the sustainability of textiles, it is becoming increasingly important to consider the entire product cycle – including the behavior at the end of its useful life. With Impranil® DLN-SD, Covestro offers a waterbased PU dispersion that is biologically degradable by microorganisms at the end of the product life cycle. The initial internal tests performed on pure polymer films without additives confirm this. The raw materials enable biodegradable coatings and composite solutions, which in turn contribute to a modern recycling economy. Under the conditions of OECD Standard 301, more than half of the dispersion is degraded within 28 days. The percentage is significantly higher than with acrylate film formers.

The aliphatic PU dispersion Impranil® DLN-SD can be used to formulate very light-resistant coatings for adhesive, intermediate and top coats. They are also suitable for other product applications, such as latex gloves and packaging.

New TPU fiber for fabrics

At Techtextil 2019, Covestro will also showcase a new fiber made from thermoplastic polyurethane (TPU). Compared to conventional polyethylene terephthalate fibers, it is characterized by an improved abrasion resistance and can be heat pressed at lower temperatures. Tear resistance and a good haptic feeling are further advantages.The fiber can be used in footwear, functional textiles, sports accessories and casual wear.

Innovative film solutions for smart textiles

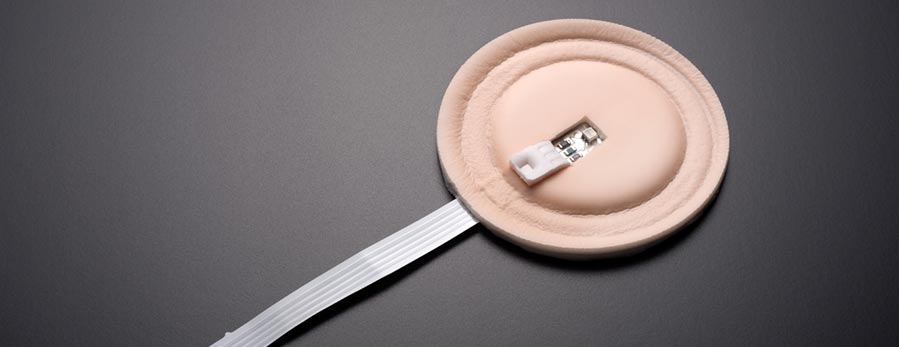

The use of printed electronics is becoming increasingly important in the course of increasing digitalization in the medical and health sector and also in leisure time. Covestro has developed a range of skin-friendly film solutions to meet the requirements for lightweight and very comfortable smart textile design. Smart textiles are an important application, for example for biomonitoring, diagnostics and drug administration.

Platilon® thermoplastic polyurethane (TPU) films are used, for example, in the continuous monitoring of vital functions and exact performance measurement. A conductive ink can be safely applied to the films to achieve this. Housed inside a shoe sole, patient data can be directly recorded and evaluated in real time by electronic devices.

Sustainable textile coatings for medicine

Recently, Covestro has also been developing textile coatings for medical applications. These include surgical clothing, bed pads for hospitals, coatings for medical furniture and even bandages. At Techtextil 2019, the company will present raw materials for sustainable, water-based textile coatings with good haptics and resistance to disinfectants, as well as cohesive bandages without latex for compression therapy and secondary fixation.