#Techtextil 2019

Thies textile machinery exhibits again at Techtextil 2019 in Frankfurt

The machines process a wide variety of yarns, fibres, nonwovens and fabrics suitable for various technical textile applications: for example aramide fibres which are used for security wear and top-end, bullet-proof automobiles.

iCone

The newly developed dyeing machine "iCone" treats yarns, fibres, flakes, cables, ropes and belts. The new technique enables dyeing in short fleet. Obtaining uniform dyes and the required fastness is self-evident. Due to the new energy-efficient (ee) functions the “iCone” is able to colour in a more cost effective and environmentally friendly way.

Another field of application is the discontinuous bleaching of cellulose fibres for medical purposes and/ or any other fibres such as polyester, acrylic and polyamide.

In the Thies product portfolio one can find the corresponding presses and dryers.

Furthermore, the variety of "iCone" is reflected in the following areas of application:

The treatment of threads, the dyeing and bleaching of yarns for the production of solar sails, tents, awnings and the finishing of hard-retardant yarns.

HT- Jigger

The Thies HT-Jigger is used for dyeing fabrics, nonwovens or space fabrics in open width form. The HT-Jigger offers stepless tension and material speed control with an economical dye trough. It has been designed to offer uniform dyeing in short liquor ratios.

Suitable to process textiles at temperatures up to 143ºC, the HT-Jigger is recommended for the treatment of crease sensitive, permeable and non-permeable fabrics; to offer optimum flexibility for finishing of all modern fibres.

Key applications are the automotive sector with, for example, treatments of vehicle interiors or industrial sectors, which use filter materials.

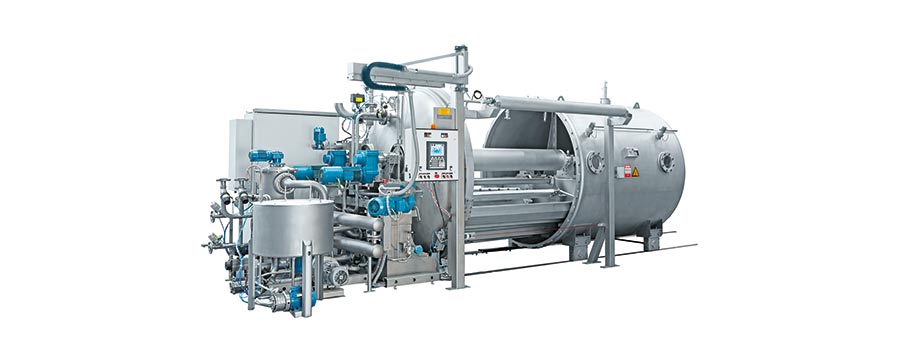

iMaster H2O

For applications where water consumption is an important consideration, together with other possible energy savings including steam, electricity plus chemicals and dyestuffs, the well- established iMaster H?0 dyeing machine is already proving successful with several automotive fabric producers. The notable process times of the iMaster H?O dyeing machines facilitate higher production capacities.

The system features a transport winch inside the kier, allowing cotton, synthetic fibres and their blends, and including articles with a high elastane content, to be processed with significantly reduced elongation; resulting in fabrics with an improved stability whilst offering flexibility in the processing of a wide range of products.

soft-TRD Slll

Designed for the universal dyeing of wovens, knits and nonwovens, this third generation of soft-TRD machines sets new standards in the efficient use of materials and resources.

The soft-TRD SIII is able to handle crease and surface sensitive articles at fabric speeds of up to 600 m/min. The free material flow and low intensive transport zone, guarantee optimum relaxation and uniform treatment of the entire rope.

The special design with its swimming material transport provides the finisher with increased flexibility in the processing of a wide range of fabrics and material weights.

Thies Multi Product Supply- System

Chemical and dyestuff feed systems complement the product range of the German Textile machinery manufacturer, Thies. The MPS-Systems supply dyeing and other finishing machines with chemicals, dyestuffs and textile auxiliaries. The individual design and the ideal synchronisation are noteworthy.

Heat recovery system

To gain energy out of hot industrial waste water is the aim of Thies’ heat recovery systems. Special tubular heat exchanger allow high efficiencies and low payback periods.

Various modern types can be connected to these systems.

The Thies team of technical textiles dyeing specialists will be on hand throughout the exhibition to offer in-depth expertise and guidance.