#Techtextil 2019

Stäubli at Techtextil – Technologies for manufacturing advanced textiles

In order to capture these advantages, the textiles must meet stringent requirements, resist mechanical forces such as compression or shear, withstand environmental conditions, or meet strict medical hygiene requirements. In addition, the fibres, yarns, and even finished fabrics are often subjected to chemical and mechanical processes during or throughout the entire textile manufacturing process.

If the textile surface is a woven fabric, Stäubli plays an important role in the design and quality of the end product, thanks to its core competencies in shedding (dobby and Jacquard machines) and weaving preparation (drawing-in and warp-tying machines). Based on over a century of experience in the traditional textile industry and its continuous R&D activities, Stäubli constantly offers new and improved high-performance systems and solutions for processing technical textiles and other fabrics – equipment that can be individually adapted to the needs of the weaving mill. The machinery described below represents a selection from Stäubli’s broad range for technical textiles:

- Magma T12 – the warp-tying solution for technical yarns - This tying machine processes monofilaments, coarse multifilaments, PP tapes, bast fibres, coarse staple fibres and many other yarn types.

- LXL/LXXL Jacquard machines for producing complex OPW (one-piece woven) airbags - These machines feature lifting motions that ensure precise shedding geometry and absolutely vibration-free movement even at high speeds. The optimally coordinated kinematics of all moving parts within the machine and the directly mounted components such as the drives enable routine weaving of very heavy fabrics. The shed opening is optimised and loads on the warp threads during weft insertion are reduced. The robust construction and uncompromising use of high-quality materials guarantee the reliability and longevity of every machine.

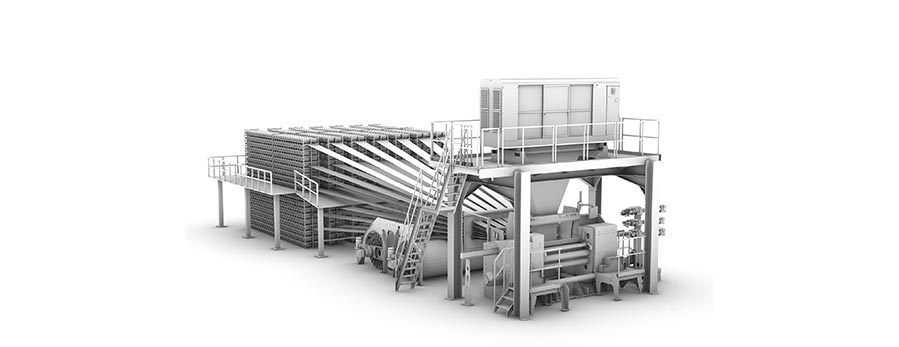

- TF20 weaving system for complex multi-layer fabrics - Individually configurable, this system allows the production of flat and spacer fabrics, complex and very thick and/or dense multi-layer fabrics, as well with material mix, and 3D textiles.

- ALPHA 500 LEANTEC for manufacturing high-quality artificial turf - This specific weaving system of the Schönherr Carpet Systems product line enables the economical production of high-quality synthetic turf and greige woven carpets.

At Techtextil 2019 in Frankfurt, Stäubli will inform visitors to its Booth B02 in Hall 3.0 about the features, details, and advantages of Stäubli’s machinery, systems, and solutions for producing technical textiles.