#Technical Textiles

IAA 2025: Redefining Mobility Through Innovation and Sustainability

The automotive industry is facing a profound transformation that goes far beyond electrification. Key future trends include software-defined vehicles, autonomous driving, connected mobility and the ongoing decarbonization of supply chains.

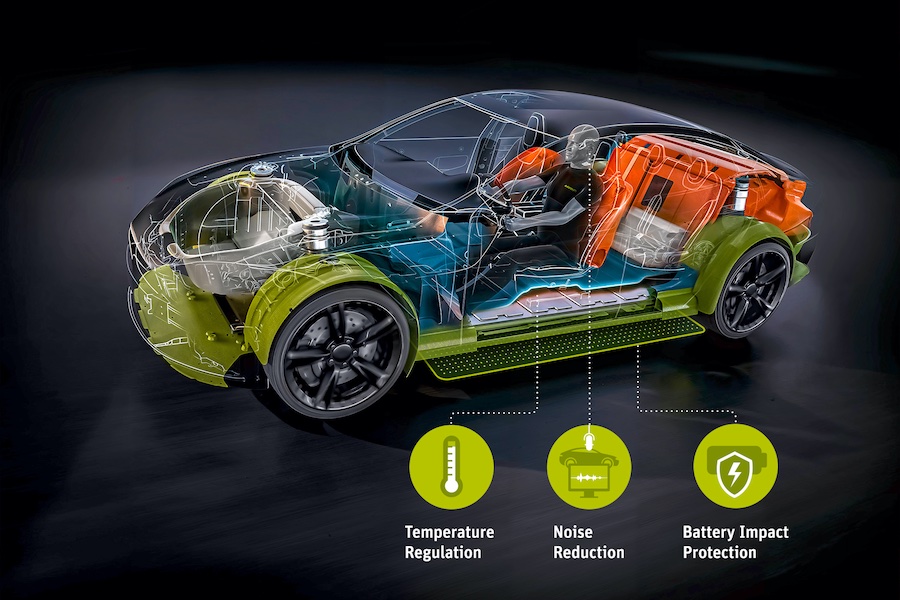

Autoneum is responding to these developments with a clear focus on innovation and sustainability. The company’s products are not only suitable for all types of drive systems, but also for the requirements of software-based vehicle architecture. With NVH solutions for quiet interiors, thermal shielding for battery modules, and fully recyclable materials, Autoneum is helping to make the mobility of tomorrow safer, more comfortable and more resource efficient.

Illustration of Autoneums products in a car

Sustainability – circular economy in action

Sustainability is a key focus. Autoneum processes over 30,000 tons of recycled PET annually – equivalent to around three billion 0.25-liter bottles. Products such as Flexi-Light PET, Di-Light, and the fully recyclable N-Join1 carpet consist of over 90% recycled material and thus make a measurable contribution to decarbonization and resource conservation.

Flexi-Light PET, a particularly malleable and durable polyester-based acoustic material, provides effective sound insulation in the vehicle interior and is fully recyclable. Thanks to its thermal formability and structural properties, Di-Light not only offers good noise insulation for vehicle carpets, but also a high degree of design freedom – ideal for large-area applications. With N-Join1, Autoneum has also developed a mono-material system that does not require any latex or adhesives. It is made entirely from recycled materials and can be easily recycled at the end of its product life cycle.

“Sustainability is an integral part of our strategy,” says Eelco Spoelder, Chief Executive Officer (CEO) of Autoneum. “With innovative materials and resource-saving processes, we are actively contributing to the transformation of the automotive industry – and demonstrating that economic success and ecological responsibility go hand in hand.”

New mobility needs new materials

According to forecasts, global sales of electric vehicles will rise to around 20 million units in 2025 – an increase of 35 percent over the previous year. The industry’s transition is also reflected in Autoneum’s product strategy. By 2024, more than 115 electric models worldwide were equipped with Autoneum components – and this figure is expected to rise to almost 150 in 2025. Sixty percent of all new orders last year were for purely electric vehicles; a significant increase compared to 35 percent in 2023.

The company develops highly specialized components for the next generation of vehicles – especially for electric vehicles with new battery architectures. With components such as the Impact Protection Plate, the mica-free E-Fiber Shield, and the acoustically efficient Ultra-Silent, Autoneum demonstrates how safety, lightweight construction and sustainability can be combined in forward-looking materials that meet the requirements of modern electric vehicles.

The Impact Protection Plate is a newly developed protective plate made of composite materials that combines mechanical strength with thermal insulation. It protects battery systems from impact and contributes to the safety and efficiency of electric vehicles. The E-Fiber Shield is a mica-free flame-retardant material that increases the safety of vehicle occupants in the event of thermal runaway of the battery. It offers high heat resistance (up to 1400°C), electrical insulation, and geometric flexibility. And Ultra-Silent is a robust, lightweight material for frunks and underbodies that consists of up to 70 percent recycled fibers. It combines high acoustic performance with sustainability.

“Our innovative strength is evident where sustainability and technology come together: in materials that conserve resources, increase safety and address the requirements of modern electric vehicles. In this way, we are making a practical contribution to the mobility transition – and creating real added value for our customers,” summarizes Spoelder.

To keep pace with this dynamic, Autoneum has its own New Mobility team in 2023 and established a new research and technology center in Shanghai, China, in 2024. This complements the existing innovation centers in Winterthur, Switzerland, and Bocholt, Germany, and strengthens global development expertise.

Local production for global resilience

In an increasingly challenging market environment, Autoneum relies on proximity to customers as a strategic success factor. With its “local-for-local” strategy, the company manufactures at around 70 locations worldwide, right where the vehicles are produced – efficiently, sustainably and independently of global supply chains. “Our local production strategy makes us resilient – even in an environment characterized by trade barriers,” emphasizes Spoelder. “Manufacturing directly in the market significantly minimizes cross-border risk and strengthens our operational stability.”