#Sustainability

SC Ready Garment Technology Romania SRL is OEKO-TEX® Company of the Month for December 2014

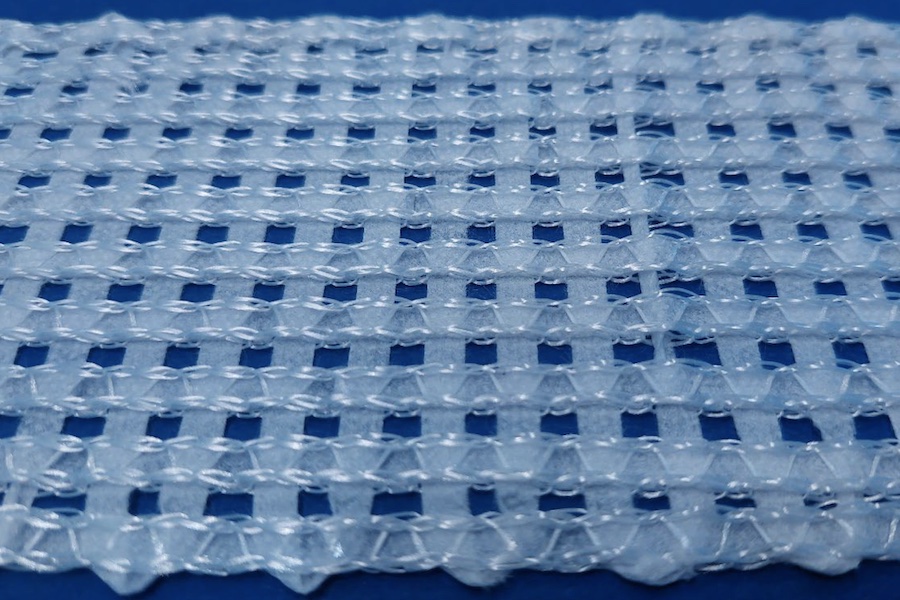

The services on offer range from different washing types and dying types to the “Finishing & Special” Effects product sector. The portfolio includes the washed look, used look and the 3D effect as well as coating with foil, and much more. In the area of dying, the company uses “Datacolor”, which is a technical solution for optimally matching colours to each other. The customer can select the required colours in the colour library. The colour spectrum is being constantly expanded to include new trendy and fashionable colour tones, which are manufactured internally. "The textile processing services are based on our specific expert knowledge and are adapted in a quick, customer-specific and individual manner" said Managing Director Dr. Dietrich Bock. A final check and quality control measures are carried out on the items of clothing even during completion and before delivery to the customers. The items of clothing are checked in strict compliance with the international standards and specifications of the buyers.

Pic: According to the provider, in 2013 they finished and produced more than 10 million parts © SC Ready Garment Technology Romania SRL

With regard to production, the company also has its finger on the pulse and consciously focuses on sustainability in production: Since the summer of 2014, Ready Garment Technology Romania has been the first and only textile company in Romania up to now to have STeP by OEKO-TEX® certification. "The demand for certified and sustainable textile production is constantly increasing. This also means that the brands of world-renowned customers need to be protected against bad press in relation to it. The best way to do so is to ensure that the company is awarded with an independent, comprehensive, transparent and trustworthy certificate" confirmed Dr. Bock.

In the future, RGT Romania plans to continuously develop their product range, in particular the opportunities in the area of "casual-sports" trousers should be expanded via full service provision. This should further strengthen the position of the company as a leading supplier of trousers for European premium brands.

In a word - Dr. Dietrich Bock, Managing Director of the Dr. Dietrich Bock & Partner holding company, explains about sustainability.

How is RGT Romania different? RGT Romania has been in the market since 2000 and since then has acquired extensive knowledge in the area of finishing parts using washing, dying and all special effects. Optimum quality and performance are achieved through continuous investment in the use of the latest technologies and in our motivated employees. As a result of the stringent demands for quality and service, RGT Romania has been able to withstand the difficult EU market as one of the leading laundries in Romania and has even managed to achieve growth. To continue to be able to meet the demands of the consistently very well-known and well regarded customers in the future, RGT Romania is working with the other subsidiaries of Dr. Bock and Partners to move from being a commission-based finishing company to become a full service provider.

Why have you chosen STeP by Oeko-Tex® certification? The market for certified environmentally friendly and socially responsible textile production is constantly increasing. This also means that the brands of well-known customers need to be protected against bad press in relation to it. The best way to do so is to ensure that the company is awarded with an independent, comprehensive, transparent and trustworthy certificate. As RGT Romania is deeply committed to innovation, it searched out a certification system that could satisfy our demands in this area, which is still so new to so many manufacturers. The certification through STeP by OEKO-TEX® allows RGT Romania to prove that our work is carried out based on European standards, both with regard to environmental impact, as well as in the area of social protection. As a result, any discussions about these critical issues can effectively be precluded. For the procedures in the operation, STeP is a helpful tool for rearranging existing processes in a comprehensive structure and allowing them to be evaluated neutrally by an independent party.

How do you implement greater sustainability in your company? In principle, RGT Romania is subject to strict EU legislation. There are also customer demands relating to human-ecological product safety and environmental impact. RGT Romania regularly verifies these through customer audits and of course independent audits such as, for example, those carried out in the course of STeP by OEKO-TEX® certification. In their efforts to continuously improve, RGT Romania always aligns itself with the best available technologies. Thus when making new acquisitions, care is always taken to ensure that the most efficient machines are purchased. The employees also play an important role as they have a good knowledge of their role in the process and receive constant further training so they can acquire more Expertise.