#Sustainability

Inditex and BASF develop the first detergent designed to reduce microfiber release from textiles during washing

- Today Zara Home will launch the new detergent, “The Laundry by Zara Home” – available at the brands’ stores and online – that reduces microfiber shedding from textiles by up to 80%

- Detergent formula features a combination of efficient BASF ingredients that gets laundry clean even in a cold wash, helping to reduce carbon emissions and extend the life of clothing

- To leverage the positive environmental impact of this solution, the formulation can be adjusted to enable the use of this technology by other detergent manufacturers

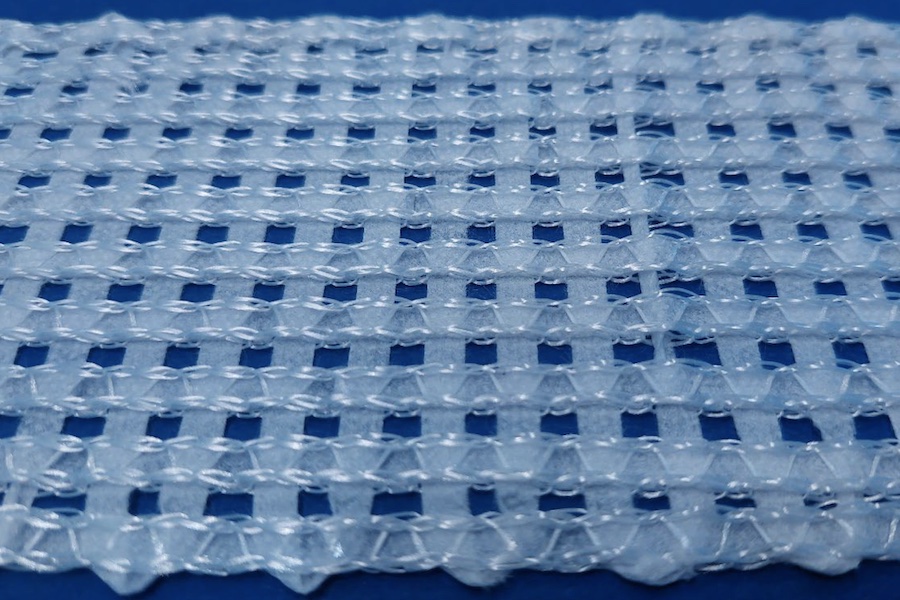

Developed jointly by Inditex and BASF Home Care and I&I Solutions Europe, in Spain and Germany, the innovative solution may reduce microfiber release by up to 80% depending on fabric type and washing conditions. These results have been tested by several research institutions.

The detergent formula containing efficient ingredients was tested in the laboratory using different textile types and washing conditions. The results show that the detergent is particularly suitable for washing at low temperatures which brings additional advantages: end users can lower their energy consumption – by reducing the temperature for example from 40°C to 20°C – and thereby reduce their carbon footprint. Colors stay bright for longer, extending the life of the textiles.

Availability

Consumers can buy the detergent at Zara Home stores and online platforms in more than 25 markets, including Spain, Germany and most of the European markets. The product will also be available at additional markets and stores in the coming weeks.

The developed solution can also be adjusted to enable the use of this technology by other detergent manufacturers. "Innovation and collaboration are key to meeting the challenges of the textile industry. We strive to be more creative and efficient by driving innovative new technologies. This project with BASF is a good example of this approach as it shows the effectiveness of cross-industry collaboration and goes one step further as it can be adjusted to extend the use of this technology in the industry," says Javier Losada, Chief Sustainability Officer of Inditex.

Soeren Hildebrandt, Senior Vice President Home Care, I&I and Industrial Formulators Europe, further adds: "We work continuously to address the growing demand of our customers for innovative and sustainable solutions. With the jointly developed laundry detergent, we are supporting the textile industry on their sustainability path and allow consumers to improve their own environmental footprint."