#Sustainability

Fashion for Good celebrates success of first year in South Asia

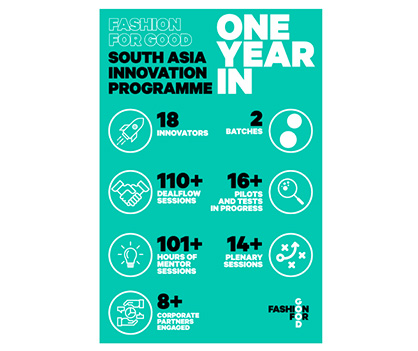

With more than 100 deal flows and 83% engagement in pilot projects, it’s encouraging to see the pace and momentum of transformation in the region, driven by the Fashion for Good South Asia Innovation Programme. We’re extremely proud to have brought together our partners, manufacturers, Arvind Limited, the Welspun Group and Birla Cellulose, and innovators to achieve so much, in such a short period, and under such adverse circumstances; we’re excited to be leading the change.” – Katrin Ley, Managing Director – Fashion for Good

SCALING ALONG THE GROWTH CURVE

Throughout the year, Fashion for Good, working closely with key supply chain players, has identified the critical challenges posed to the circular transformation in the region; the lack of knowledge around circular solutions, the lack of capacity to work with innovations, the lack of funds to invest in new technologies, and lastly, the limited engagement from major fashion brands. In a newly released report “The State of Circular Innovation in the Indian Fashion and Textile Industries”, Fashion for Good highlights these challenges as well as the opportunities for innovation and investment. Fashion for Good addresses these challenges through their programmes to accelerate and scale these technologies as well as through collaborative initiatives with key players in the industry.

DRIVING INNOVATION AND COLLABORATION

Scouting over 300 innovators from the region, the programme launched early this year with its first selection of 9 innovators, graduating today, and welcoming an additional 9 into their second batch in July. Aiming to scale these technologies through initiating opportunities with industry players, the programme orchestrated over 16 pilots and tests over the past 12 months.

Projects of note include; a collaboration between plastic recycling innovator Lucro and Welspun Limited to close the loop on their packaging waste stream; KB cols, a technology that extracts natural colours from waste that can be applied to textiles, is testing their solution with three partners; Descatuk and Birla Cellulose co-developed eco yarns that incorporate Descatuk’s unique New Natural Fibres (NNF); and most recently, Textile Genesis, a traceability platform using blockchain, together with leading brands BESTSELLER and Kering, join a Fashion for Good led consortium project, the Viscose Traceability Project, to trace the viscose fibres used in 8 garment styles across their supply chains.

Find out more about what the Fashion for Good South Asia Innovation Programme has achieved here: https://fashionforgood.com/south-asia-programme/

REGIONAL PRESENCE AND NEW PARTNERSHIPS

Concluding a successful year of establishing a footprint and successful partnerships in the region, the South Asia Innovation Programme welcomes Birla Cellulose (who earlier this year joined Fashion for Good’s consortium project, Full Circle Textiles Project) as a regional innovation partner alongside launch partners Welspun and Arvind Limited. Birla Cellulose is a global leader in the man made cellulosic fibre industry, pioneering sustainable practices such as sustainable forestry, climate change initiatives, water conservation, innovations in alternative raw materials, Higg FEM, traceability and several other areas. The addition of Birla Cellulose to Fashion for Good’s existing network of global brands and manufacturers further engages pivotal supply chain actors to accelerate industry transformation.

In addition, Fashion for Good is engaged with a number of small scale, regional manufacturers in order to test and implement innovations, and is working closely with investor and expert communities, as well as universities to generate deeper impact within the regional fashion and textile industry.

“Our partnership with Fashion for Good is aligned to our strategy of partnering for creating bigger and broader positive sustainability impacts. We believe that the transformational changes can not be achieved without ground breaking innovations. The future belongs to companies which can learn to collaborate and drive innovation for the benefit of people, planet and profit.” – Mr Dilip Gaur, Business Director, Birla Cellulose, Aditya Birla Group & Managing Director, Grasim Industries Limited