#Associations

Sustainability – innovating to meet the challenges

Since antiquity, humans have been exploiting color to enhance both our personal appearance and the world we live in. Dyed and printed textiles are a prime example, with a huge global coloration industry developing over the centuries. However, the massive consumption of water and energy required by many finishing processes, as well as the toxicity of some chemicals, has increasingly caused grave concern to environmentalists and the wider public. Conversely, responding to these worries has been the catalyst for innovation among eco-responsible companies in the Swiss Textile Machinery Association.

Green-tech denim dyeing

Washing processes, solvents and dyes in manufacturing account for one-fifth of industrial water pollution, according to the `State of Fashion 2020´ report by consulting firm McKinsey. This is the kind of evidence which sparks urgent calls to action addressed to politicians – as well as textile brands.

But the Swiss finishing machinery companies need no such wake-up call: for years, many of them have been actively developing and launching innovations with environmental friendliness as a prime requisite. An example is research into dyeing process which work without hazardous chemicals. At ITMA 2019, green technology denim dyeing became a reality with Smart-Indigo™, a Swiss innovation by Sedo Engineering, introduced at the show. The underlying breakthrough was the ability to industrialize the electrochemical process for reducing indigo, using only electricity. The dyestuff is produced by an electrochemical process, consuming considerably fewer resources than existing methods. The method uses only indigo pigments, caustic soda, water and electricity. In a fully-automated system, clean dyestuff is produced, metered and fed directly to the dyebath. Smart-Indigo™ is the most sustainable way to dye denim for jeans.

Ecological profitability – no contradiction

The finishing industry today demands machinery which meets ecological requirements at the same time as enabling mills to operate profitably. That was the motivation behind the development of ESC (Energy-Saving Chamber) under the Santex brand of Santex Rimar Group. By re-using exhaust air from the Santashrink dryer, ESC increases production capacity by 15 to 17% from the same amount of heating energy. Maximum performance at low energy use, for low residual shrinkage, soft hand feel and surface luster is the goal of Santex machines. The specialized open-width fabric surface treatment systems always offer energy-saving options for sustainable production and low CO2 values – along with the promise of a return on investment in 1.5 years.

Two approaches to water savings

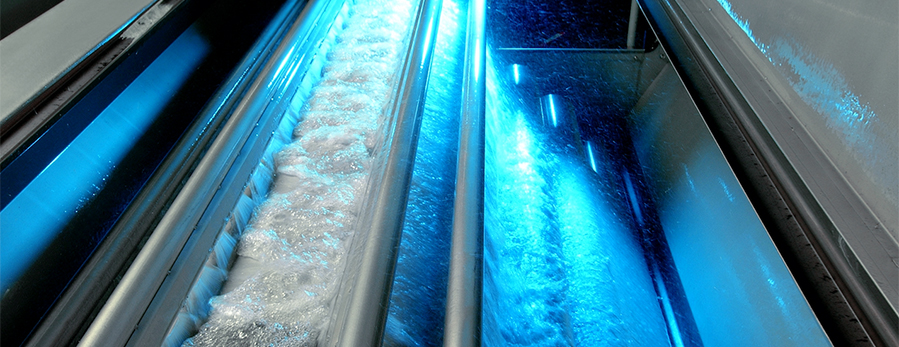

At Jakob Muller, top-quality technical parameters go hand-in-hand with the necessity for environmentally-friendly production in its innovative efforts. For example, its new washing module fulfils product and environmental needs, thanks to improved washing-off results with less energy and water consumption. It is important to the company that any dyeing processes use recycled water wherever possible. “Water is the most critical resource in dyeing. Advanced as well as less-developed markets are forced to face this challenge, which offers innovative suppliers new opportunities in markets that were previously closed,” says Christian Lerch, Head of Global Sales and Marketing, Jakob Muller AG Frick.

Open-width finishing equipment specialist Benninger tackles another important environmental issue in one of its latest developments by measuring pollution levels in the washing process. A sensor automatically gauges the level of pollutant, so that only the required amount of water is fed into the wash chamber, ensuring minimum use of both water and energy, and high reproducibility of the washing result. This is part of Benninger’s commitment to investing in resource-saving technology, offering recovery processes for heat, waste water and chemical leaching.

Testing for sustainability

Producing laboratory and testing instruments, as well as customized production machinery, Mathis has a strong basis of expertise in the dyeing and coating sectors. The company understands the importance of quality assurance related to both performance and durability in applications such as sport and leisure. And equally vital is the role of effective testing of product sustainability, as a key element in customer satisfaction.

Textile dyeing and finishing is one of the most chemically-intensive industries – a fact acknowledged by Swiss machinery manufacturers. As Benninger Group CEO Beat Meienberger says: “We have invested a great deal in resource management and our equipment offers valuable features to make this industry more sustainable. Solutions are customized, based on sophisticated technologies and showing high quality for a long lifespan. Targeting sustainability can be more than just lip service – but it has its price.”

Sustainable finishing processes are the only way to save the planet. Companies can make sustainability real with innovative solutions from members of the Swiss Textile Machinery Association. With developments which minimize water and energy consumption and tackle the challenge of hazardous solvents, Swiss technology is ready for change.