#Spinning

Discover Saurer's innovations at Febratex 2024

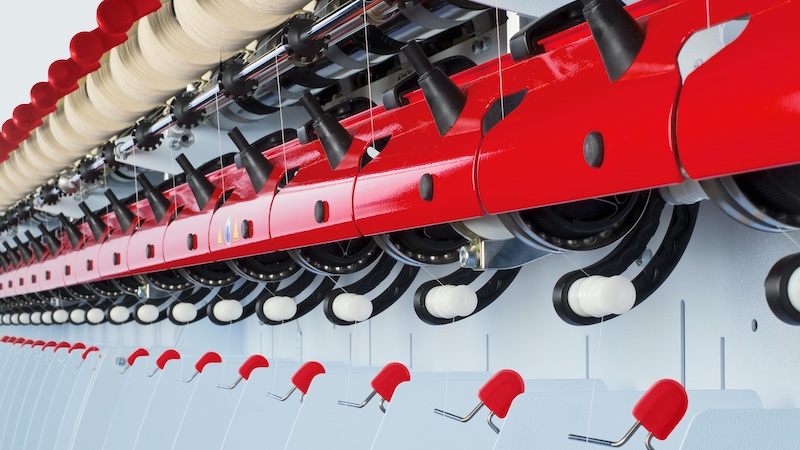

During Febratex, Saurer looks forward to showcasing the Saurer machine portfolio which is perfectly suited to the needs of the South American textile market. Whether customers are looking for spinning preparation, roving frames, or flexible solutions in ring, compact, rotor and air spinning, the Saurer portfolio covers it all. Saurer offers a variety of options for the use of recycled fibres in all process steps of the spinning mill.

Saurer spinning and twisting machines guarantee maximum productivity with minimum manpower. This is the result of the automation features that are already built into the machines. In addition, Saurer offers a complete range of automation solutions that can be tailored to the customers' specific spinning and twisting requirements.

Spinning solutions

Saurer's Autoairo 11 air spinning machine sets new standards in productivity, automation and efficiency for economic air spinning and is now processing cotton and cotton blends. The Belairo yarns produced on Autoairo 11 are an ideal choice for terry towels and polo shirts, but also for commodity yarns.

The new Zinser 51 is available as a ring- and compact-spinning machine. Zinser 51 is designed to deliver excellent yarn quality, while being equipped with energy saving solutions and Texparts quality components.

With its focus on automation, digitalisation, and ergonomics, the Autocard SC7 en-ables mills to achieve more production and higher sliver quality with less manpower.

The fully automated rotor spinning machine Autocoro 11 can process even the shortest fibres in the Recycling Xtreme version. The Autocoro 11 also offers additional 10% energy savings compared to Autocoro 10 and more powerful automation. The BD 8 semi-automatic rotor spinning machine is an ideal partner in the field of recycling spinning. Now BD 8 is supplied with up to 4 automatic doffer units (DU) and Twinsuction.

Twisting solutions

The latest developments in twisting will be explained by Saurer experts. The CompactTwister offers new standards in twisted yarn quality, is very flexible and robust, requires less space and is easy to maintain. With its twisting machines, Saurer focusses on reducing energy consumption, resulting in lower costs per kilogram of twist produced.”

Discover the latest Texparts product innovations for the textile industry: For ring-, compact- and rotor-spinning Texparts offers a lot of components: such as high-quality drafting arms, long-lasting rings and travellers and energy-saving Eshape spindles, which can save up to 6% energy.

Retrofit and upgrade solutions

Saurer offers retrofit and upgrade solutions to reduce the energy consumption of existing spinning machines, because every Watt that spinning mills can save matters to our planet. Upgrade and retrofit kits are also available for processing recycled fibres. The Saurer service experts will advise customers on retrofit solutions to extend the life of existing Saurer machines and implement new features at the same time.