#Spinning

Up to 5% efficiency boost with Nema, SSM Digital Suite

The Challenge

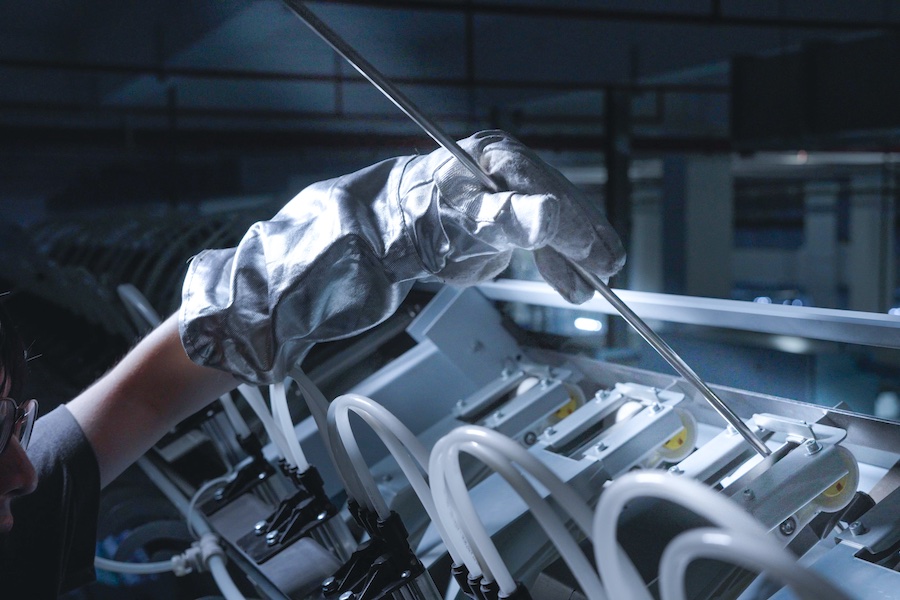

AMANN products stand for quality and reliability. Delivering premium threads at a high production rate with as little waste as possible and few to zero defects is a constant challenge. With eight production sites in seven countries, the challenge gets even more complex. Being able to get an overview, in real-time, of the complete machine fleet performance is key to minimize downtime and waste while ensuring a high level of quality.

The Solution

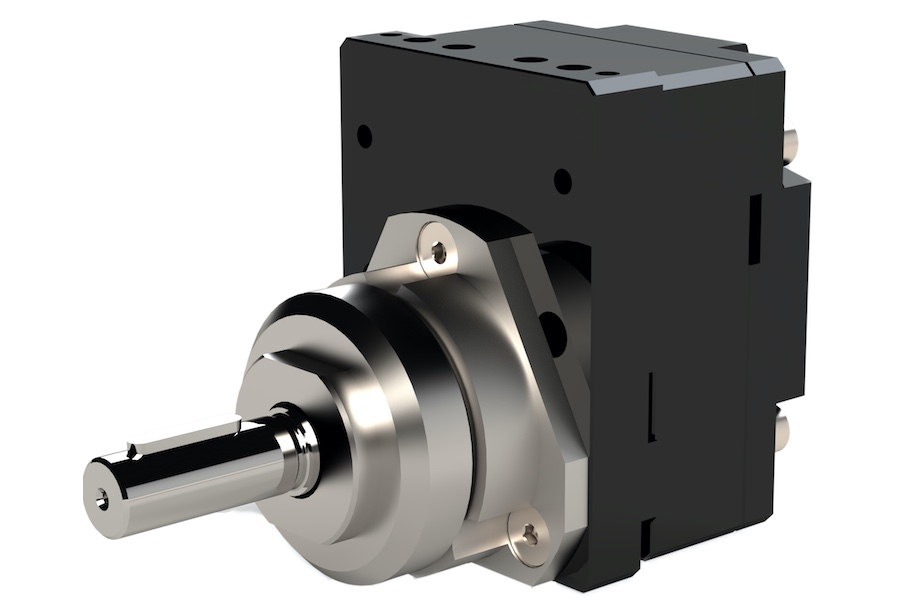

Nema, SSM digital suite, allows a near real-time monitoring of all connected machines, 24 hours a day, regardless of the machine location. A graphical dashboard provides a clear view of all key performance indicators at a glance. Machine health is thus monitored in near real-time; any deviation is quickly recognized and actions can be implemented in a timely manner.

The Customer’s Benefits

Nema delivered to its promises. After three months, AMANN could already optimize its manufacturing workflows, resulting in more than 5% higher efficiency in average. The company is now able to get real-time insights on manufacturing conditions in all connected plants worldwide in order to take quick actions, if needed, and thus keep downtime to a minimum. The best performing machine can also be identified, and its settings duplicated for high productivity with close to zero errors.

Combined with SSM high precision winding, finishing and yarn processing machines, Nema gives AMANN a competitive edge and opens new perspectives.

"To compete with the pace on textile market, where contributions like fastest customer service and higher customer flexibility are redefined everday, we have to constantly get current KPIs to monitor efficiency and push for the best possible capacity. Nema is a great tool to understand the efficiency of each machine and each position. With further details like stop reasons, it gives us clear information where to look for possible improvements at the GEMBA. The combination between Nema and the robust and reliable high-performance machines from SSM is required to keep up with the market and customer challenges."

Christian Scholz, Director Global Industrial Engineering at AMANN Group