#Recycling / Circular Economy

Rieter and Recover: Cooperation in the field of recycling

Rieter and Recover agreed to join hands for technological advancements and research projects in the field of recycling. Both parties will work together to conduct trials and initiatives with various recycled raw materials and blends to build a solid foundation for textile circularity.

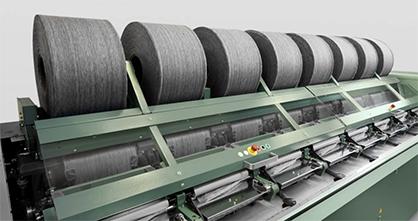

Rieter has high competence in customized spinning systems for staple fibers including recycled materials and Recover has developed its expertise in processing and applying high-quality recycled fibers. Both parties are expected to create synergies by improving the processing of pre-and post-consumer recycling materials.

Recover™ and Rieter partner to reshape sustainable textiles

This joint cooperation is betting on ambitious research that hopes to increase the availability, applicability and use of recycled textiles as raw materials.

Agents of change: investing in the future of recycled fibers

Potential new blends

Rieter and Recover™ have joined hands to develop technological advancements and research projects in the field of recycling. Both parties are working together to conduct trials and initiatives with various recycled raw materials and blends to build a solid foundation for textile circularity.

Specifically, they are working to amplify Recover's catalogue of blends, Recover announced in the press release. The challenges lie in mechanically recycling diverse fabrics without sacrificing the integrity of the resulting fiber.

New horizons for post-consumer textile waste

Most of the textile waste Recover currently recycles is either post-industrial or pre-consumer as both are easier to sort – by composition and by color. Post-consumer waste, on the other hand, is more challenging as pieces’ composition varies widely (from 100% cotton to cotton/polyester blends and rayon).

With Rieter, Recover hopes to change that. They’re working side by side to be able to scale the recycling of post-consumer textiles and still produce the highest-quality recycled fiber.

Rieter has high competence in customized spinning systems for staple fibers including recycled materials and Recover™ has developed its expertise in processing and applying high-quality recycled fibers. Both parties are expected to create synergies by improving the processing of pre-and post-consumer recycling materials and to extending the scope of use of recycled fibers with improved processes and machines.

Improved traceability

Rieter and Recover™ are collaborating with 3rd parties such as universities to verify how much recycled fiber is left in the yarn when applying new processes. This collaboration is expected to help the textile industry enhance the competence of verifying real recycled material usage.

Promising alliances for a promising future

"We’re excited to see where this cooperative research takes us. We’re thrilled to continue working alongside Rieter as we work towards a circular textiles future", Recover said in a statement.