#ITM 2022

Marzoli demonstrates “Textile Engineering” at ITM

- Marzoli exhibits at ITM, the most important exhibition for the textile sector in the Turkish market

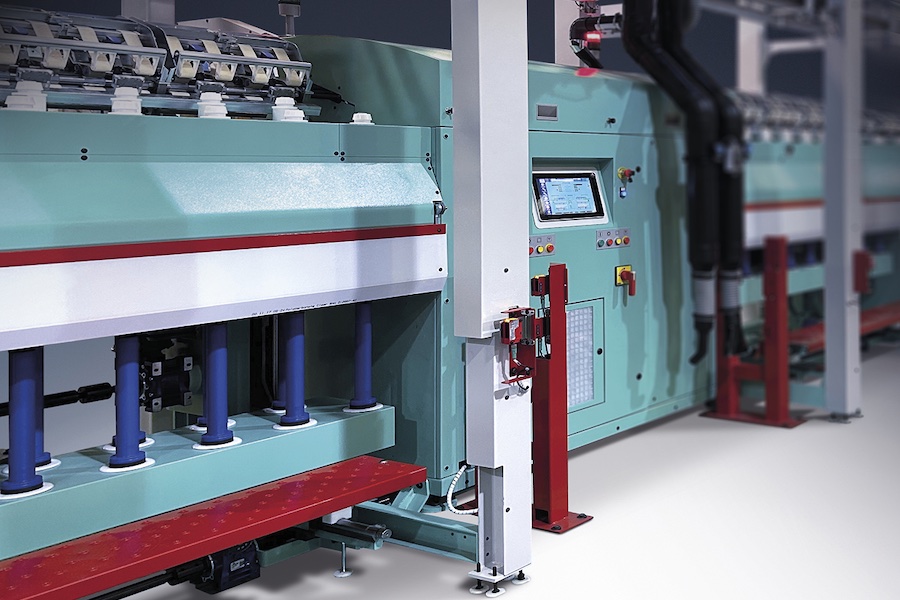

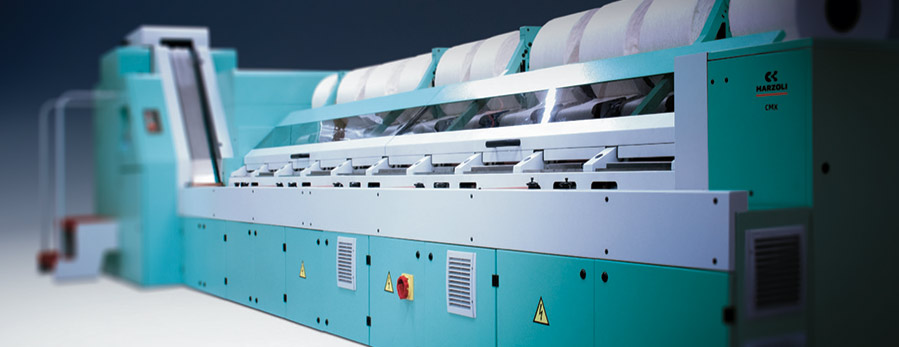

- CMX: the new state-of-the-art of combing technology

- Unique solutions for the nonwwoven sector and innovative circular technologies will be shown

Marzoli has spent the previous ten years concentrating its efforts on research and innovation in order to develop an exclusive textile engineering concept that now consists of four distinct, interconnected, and complementary technological areas:

- Spinning technology

- Digital textile

- Nonwoven solutions

- Circular technologies

The phrase “Textile Engineering” – incorporated in the Marzoli’s logo – perfectly expresses this ability to innovate and work in close contact with customers, supporting them to create value, providing the know-how able to support the customer throughout all phases of the process: from feasibility and preliminary studies to plant construction, line start-up, optimisation, management and subsequent commissioning. Added to this: staff training and organisation of maintenance activities; turnkey solutions and support in financing activities; business plan development; automation level analysis and project management.

This approach makes Marzoli the global partner for the textile industry of the future.

SPINNING TECHNOLOGY

Marzoli is one of the leading manufacturers in Europe of complete lines for opening, preparing and spinning natural, synthetic and technical fibers.

At ITM, Marzoli will display the new state-of-the-art combing technology: CMX, the unique 10-head combing system which, with a capacity of up to 115kg/hour, guarantees a level of productivity 25% higher than the previous model, along with energy savings equal to 20% kW/kg.

DIGITAL TEXTILE

Another company strength is the expertise in developing the most advanced digital technologies: at ITM Marzoli will present 5 solutions for a fully digitalized spinning mill.

Marzoli (Marzoli Remote Maintenance): the world’s first AI based platform able to analyse Big Data generated by machinery processes and also to continuously monitor mission critical operations. This ensures a reduction of machine downtime, a longer useful life of parts, and more timely and effective maintenance.

Alongside this, integrated management can be enabled by YarNet, highly innovative software, through which users can easily manage the entire Marzoli spinning process directly from their PC. With it, every machine in a plant can be monitored with ease – a real value-added technology for customers aiming to maximise productivity and profitability.

Brain Box: the patented Marzoli software with an integrated APP, based on AI technologies, which significantly improves plant performance. Tests confirm that Brain Box can generate a 5.5% increase in productivity, an 8% increase in efficiency, and 1.5% in energy savings. Installation is a fast and simple four-step process: mount sensors to each machine, connect the sensors to Brain Box, download the APP, and activate the monitoring function for the detection of any issues.

TAOMAPP: the innovative approach to cotton analysis in which the trash level inside the cotton is accurately determined through photographs taken by smartphone. It is based on ultra-high resolution image recognition techniques and quantifies the results on the Marzoli Trash Index. You just need to download the app, start the analysis and get the benefifts.

Trash Analyzer: the automatic tool that, together with Marzoli software platforms, analyses cotton’s trash content to optimise machinery set up. It can be applied wherever there is a flow of material in a pipeline.

These 5 solutions, constantly monitoring machines and process performance, allows to make intelligent and informed decision, based on constantly updated information. Each of these decisions is a further step to increase the flexibility and customization and to reach the highest level of efficiency and productivity to become more valuable on the market.

NONWOVEN

Marzoli will also be showing its innovative solutions for the nonwoven sector at ITM. With its deep experience and technological knowledge in fibre preparation, Marzoli is uniquely qualified in the implementation of plants for nonwoven products. By developing strategic partnerships with each customer, bespoke nonwoven manufacturing lines, can be developed, with each one based on exact production needs.

Range of applications: wipes, medical-surgical, disposable and filtration products.

CIRCULAR TECHNOLOGY

The circular economy, embracing sustainability, recycling and other green disciplines, will be another important topic at ITM. Since 2012, Marzoli has focused on continuous innovation in the mechanical regeneration of textile fibres. Marzoli know-how focuses on the transformation of post industrial and post consumer textile waste, creating high-value recycled fiber to be process with ring spinning tecnology.

“For Marzoli, developing and adopting green technologies means carefully balancing business needs with environmental sustainability, explains Cristian Locatelli, Marzoli General Manager. “Circularity through fabrics regeneration, is creating a synergetic value chain that benefits all stakeholders. The new paradigm of a circular fibre supply chain will accelerate learning and development of know-how pushing innovation and opening up to new potential.”