#Spinning

YarnMaster® prisma for clear reasons

Perfection for compact yarns – The General Managers of Kohinoor Textile Mills Limited Pakistan know exactly what they need for their business and are again relying on the latest Loepfe technology for, clear reasons – a new level in yarn quality with increasing profitability.

Mr. Muhammad Irfan, General Manager of the Gujar Khan plant and Mr. M. Jahanzaib Baloch, General Manager of the Rawalpindi plant lead one of the most successful textile businesses in Pakistan. They operate nine units with 180,000 spindles, covering the complete range of coarse and fine count yarn from natural to man-made fibers. Kohinoor Textile Mills Limited is known for its consistent yarn quality. The focus on satisfied customers has proven itself and is continued meticulously. This is achieved, among other things, through the constant integration of the latest technologies.

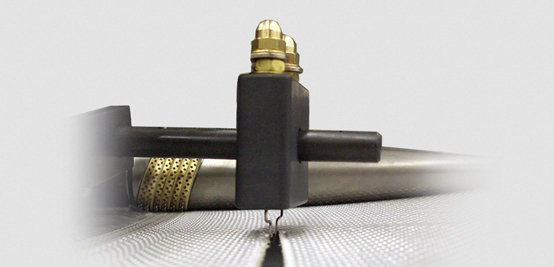

A total of 5,500 Loepfe yarn clearers are integrated into the spinning process, with the first 1,112 winding units now being replaced with the new yarn clearer generation, YarnMaster PRISMA. The motives are clear.

Mr. Muhammad Irfan commented: “Loepfe yarn clearers have helped us to improve our yarn appearance and customer satisfaction. We are delighted to continue our relationship with Loepfe by installing YarnMaster PRISMA on our lines – and, in fact, we are already seeing the benefits of this new leading-edge sensor technology.”

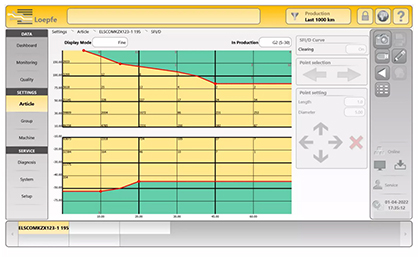

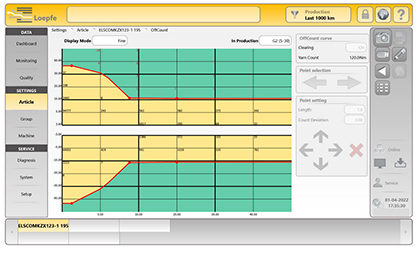

With PRISMA, Kohinoor Textile Mills Limited achieves a new level in yarn quality while increasing profitability. This is accomplished through the unique four-sensor technology combined with the intelligent clearing algorithm. Especially important for Kohinoor Textile Mills Limited and their mainly compact ring yarn production are the additional fine classes of SFI/D and OffCount clearing. The refined matrices simplify the settings and provide flexibility to adapt the clearing curve to all market needs. Thereby the compact spinners are given the best yarn structure overview of their produced yarn.

Kohinoor Textile Mills Limited uses the unique feature based on the continuous monitoring length of 80 meters for SFI/D clearing and 50 meters for OffCount clearing. Removing long faults in one piece delivers significant advantages:

- Increased machine efficiency due to less splice cycles and immediate alarm of bad bobbins after the first few meters

- Increasing yarn quality due to complete removal of long faults

- Certainty in yarn quality since no remnants of longer faults are processed further. As this is the case with other yarn clearer models which are cutting longer faults on their set curve and therefore slicing faults into pieces

Mr. M. Jahanzaib Baloch added: “KTML is a vertically integrated set up producing yarn for its own requirement and selling in the local market at the same time. Finished goods are sold to world-famous brands in the US and Europe. Quality is ensured in each and every step. The export market is very sensitive to contamination. To achieve this objective Loepfe and Service traders are our partners for decades. PRISMA is an excellent product made it possible to optimize at the deepest levels. There is a world full of opportunities in a single sensing head. For us, Loepfe is a brand we trust on.“

Immediate and professional support in all matters is a pillar of Loepfe customer care. If our customers are satisfied. Then so are we.

Thank you Kohinoor Textile Mills Limited for your loyalty and we look forward to hearing more about your successes in the coming months!