#Spinning

Sustainable and intelligent: The TC 19i sets the benchmark for energy-efficient carding

Only the intelligent Trützschler card TC 19i features the unique T-GO gap optimizer, which continuously and automatically monitors and adjusts the carding gap to an ideal position during production. By now, more than 2000 intelligent cards sold worldwide prove quality and production leaps in the double-digit percentage range daily, thereby reducing energy demand per kilogram produced.[3] Innovative drive- and air technology further reduce energy consumption of the TC 19i. In this way, the TC 19i saves energy to help protect the planet – and also boosts profitability for yarn production.

The most energy-intensive elements in a carding machine are the drive, the dust suction process and the compressed air system. Permanent suction is needed to remove dust and cotton waste in key places. In contrast to Trützschler cards, many cards on the market also use compressed air for suction hoods in the pre-carding and post-carding areas, for example. Smart optimization of these areas has made the intelligent card TC 19i a benchmark for energy efficiency in carding because it uses less electricity, lower suction pressure and less compressed air than other machines, while providing the highest production rates currently available on the market.

In a head-to-head comparison between the TC 19i and a high-performance card from a competitor, the TC 19i consumed at least 10 % less energy per kilogram of material produced when manufacturing rotor yarn from a cotton and cotton waste mix. The compared energy values included electric power consumption and energy required for suction and compressed air and were measured in both cards at the same production of 180 kg/h. A 10 % reduction in energy per kilogram of sliver produced, as proven here by TC 19i, can have a significant impact on a spinning mill’s profitability; annual savings worth a five-digit sum are frequently possible, depending on factors such as the output of the mill. The customer trial also showed TC 19i’s excellent reliability at the customer’s usual production rate of 180 kg/h, and even demonstrated stable performance at 300 kg/h in the same application. Because the TC 19i with T-GO gap optimizer realizes maximum production rates at no compromise in quality, manufacturers can reduce their energy demand and investment costs drastically: Less machines are needed to achieve the desired output, and energy consumption per production is reduced.

Energy-efficient air technology

Next to increased productivity, air technology plays a pivotal role in the energy balance of TC 19i. Christian Freitag, Head of Air Technology at Trützschler, explains how he optimized the TC 19i in this area: “First, we reduced the need for compressed air wherever possible,” he says. “And second, we reduced suction pressure and air requirements for suction. All of our air collectors, for example, are carefully developed to eliminate potential resistance and facilitate an ideal flow.”

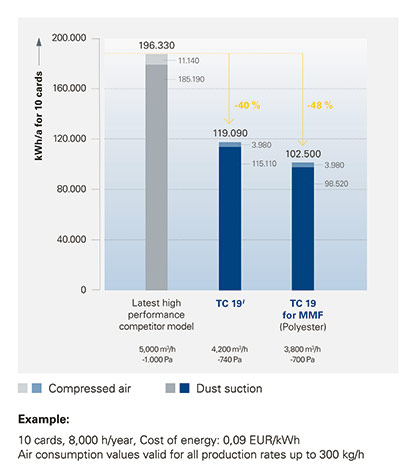

This improvement was made possible by a long and sometimes challenging innovation process involving mathematical models of air flows, as well as flow simulations and prototypes. By combining the final flow-optimized parts in the TC 19i, Trützschler’s experts have developed a card that operates with suction pressure of just -740 Pa and with an air requirement of only 4200 m³/h. This translates into 40 % less energy demand for air technology compared to the latest high performance competitor model.

“These achievements are fantastic – but we didn’t stop there,” says Ralf Helbig, R&D Engineer for Air Technology at Trützschler. “We have also made it possible to further reduce energy demand in polyester applications, which are increasingly important to our customers. In a polyester configuration, the TC 19i can reduce the necessary pressure for waste suction by a further 14 % because of improvements to elements in the pre-carding and post-carding areas, and the removal of suction hoods. The suction is still just as reliable – but it needs much less energy.”

Good for the environment – and for the balance sheet

With its unique gap optimizer T-GO, its state-of-the-art drives and optimized air technology, the intelligent card TC 19i is leading the market for energy-efficient carding. No other card can match its stable performance at such high levels of productivity, or its consistent quality and energy efficiency. As a result, the TC 19i makes a valuable contribution to global sustainability – and makes mills even more profitable too.

How to reduce energy consumption in carding?

1. Making smart investments?Choosing solutions that achieve the required (or better) quality at the highest possible production rate allows to reduce energy consumption per kilogram of output produced. The single card’s requirements for suction and compressed air should be as low as possible. In the best case the machine should also offer automatic adjustments for critical settings that affect energy consumption, e.g. carding gap setting.

2. Monitoring cylinder speeds?Realizing the desired production and quality with the lowest possible cylinder speed saves energy. Our Trützschler service provides expertise and advice in this area.??3. Optimizing carding gap settings?The carding gap should always be optimized with regard to the material and environmental conditions. If the carding gap is too wide, quality deviations might be the result. If the gap is too narrow, card wire might get damaged. When manufacturing man-made fibers, a too narrow carding gap can lead to excessive flat waste leading to friction between flat and cylinder. The cylinder will need more energy for rotation. The TC 19i, for example, automatically and continuously adjusts the carding gap to those settings that are ideal for the respective cotton or man-made fiber materials.

4. Choosing the right card clothing?Using flat top clothings that are too fine, for example for man-made fibers, may lead to a higher rate of flat waste which results in friction between flat and cylinder. This will not only slow down the cylinder, but also increase energy consumption and the amount of unnecessary waste. Trützschler card clothing solutions and service ensure that you make the right choice for your application.

References

(1)

https://www.statista.com/statistics/265598/consumption-of-primary-energy-worldwide/

(2)

https://ourworldindata.org/energy-mix

(3)

Increased production leads to higher power consumption per hour. The increase in output outweighs this factor so that power consumption per kilogram of card sliver produced is lower.