#Spinning

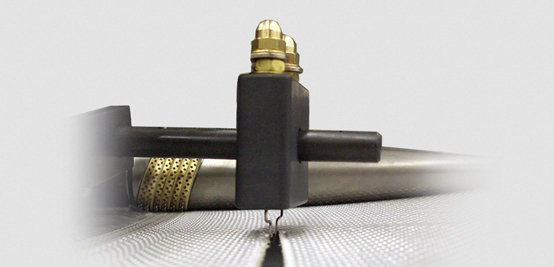

Loepfe Yarnmaster® Prisma offers innovative RGB full-color monitoring

This unparalleled full color functionality heralds in a new era of foreign matter detection. Enabling unprecedented reliability in the detection of foreign matter - in all colors – even delicate shades and whatever the glossiness differences, in any type of yarn, or indeed in any color and mixtures thereof!

Beyond that, the RGB technology allows a new color-based determination of organic materials within the yarn to separate them from regular disturbing foreign matter. These organic materials, in particular, do not necessarily have to be removed from the yarn during the winding process, as they are eliminated in subsequent processes anyway. Important factors such as these are taken into account by YarnMaster PRISMA and given the highest priority. This is because the precise detection and classification of a disturbing or non-disturbing defect leads directly to a lower cut rate, which immediately results in higher efficiency and waste reduction. This is an absolute MUST for the efficient and effective performance of a spinning mill.

The YarnMaster PRISMA yarn clearer system is the right choice for every spinning mill. Starting in basic yarn clearing where already a massive increase in efficiency - while keeping the chosen quality - can be achieved. Going further, through all quality levels up to the absolute super-yarn that is free from defects which could not even be seen by the human eye.

In summary, the YarnMaster PRISMA enables the spinner to reliably guide the yarn quality control completely according to his needs while balancing its efficiency and quality. This aligns fully to meet Loepfe’s ultimate goal - ‘we want YOU to perform’.

30 years ago, in 1991, Loepfe took a pioneering role in the introduction of foreign matter detection based on the SIRO yarn clearing principle. The degree of raw material contamination has not improved since then. The ability to control the contamination in yarns is therefore still of greatest importance to spinners. With YarnMaster PRISMA, Loepfe once again assumes the leading role and elevates yarn clearing to a new level - providing maximum reliability in foreign matter detection.

Open up new worlds - the YarnMaster® PRISMA generation!

This next-generation yarn clearer system focuses entirely on the spinners’ needs. The four-sensor technology guarantees the four key benefits - Productivity, Profitability, Versatility and Reliability - at all times.

YarnMaster PRISMA represents the new benchmark that opens up new worlds where efficiency and quality are in balance, yarn waste and energy are reduced, one device covers all challenges and Swiss-made quality is the standard. Get ready to dive into new worlds:

• Productivity Balanced efficiency and quality

• Profitability Yarn waste and energy reduction

• Versatility No limits in material, color, climate, yarn count

• Reliability Swiss-made and first-class service