#Spinning

Interview with Dr. K.V.Srinivasan - CEO Premier Group India

With a workforce of around 5,000 people, the company is focused on providing excellent customer service using latest technology, investing in eco-friendly processes and drawing on their own deep technical experience.

Interview

Loepfe: How important is the Testmode feature to Premier and how do you use it?

Dr. KVS: The Testmode feature is very useful because it’s really important to optimize the cuts-to-faults ratio in order to maintain optimum productivity. In fact, we constantly monitor the number of cuts in the yarn. While we know the type of fault we need to remove, depending on whether we are working on yarn for knitted fabrics or woven fabrics, Testmode enables us to fine-tune our approach.

Loepfe: Which problems can be solved with the help of Testmode?

Dr. KVS: There are two issues here. Firstly, you want to remove the faults - but secondly the more cuts you make mean that more splicing is necessary. The splices need to be perfect – and today this is a critical factor when producing high quality single compact yarns with finer counts. So, there’s a balance to be achieved and Testmode supports our decision-making process. Then, there’s also the issue of waste – Testmode has a role to play in reducing waste. We are also looking at still further optimization with the help of Testmode.

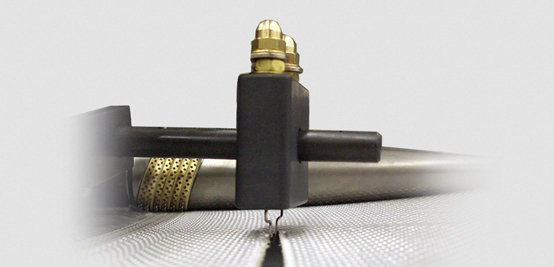

Loepfe: What is your opinion on Loepfe yarn clearers?

Dr. KVS: We have been happy with Loepfe yarn clearers and also the service and support received. Four or five years ago, we also invested in the Loepfe MillMaster product and this has particularly impressed us. From a management perspective, the various MillMaster reports help us to evaluate the performance of the spinning mill. It shows the maintenance and efficiency of the clearers, which is crucial in ensuring productivity.

Loepfe: What do you rate most positively?

Dr. KVS: Currently, we are very excited about Loepfe’s YarnMaster Prisma. We are in the process of buying a new wet-splicing winding machine and after seeing Prisma at the ITMA exhibition, we have taken the clear view that while we are buying new machinery, we should invest in the very latest sensing technology as well.