#Spinning

"You need to make the best out of this time!"

1. The year 2020 is coming to an end and you’ve been in position as Loepfe’s CEO for 8 months now. A new company, a new industry, and, on top of this, the Covid-19 coronavirus pandemic – how has this new challenge been for you?

First of all, it’s been great having you as a colleague and secondly, it has been good to have onboading during this time because actually on the one hand I was able really have deep dives with people in this company who were actually not travelling

Secondly, I was able to have some time to analyse the facts and figures that we have on hand. And thirdly, we all got to use MS Teams and other instruments to engage with our external stakeholders.

However, on the other hand, there was the big downside that I was not able to meet people physically, in person, in particular it took some time – a few months – until I was able to meet my colleagues and in particular the external stakeholders such as our customers, our agents and for example also our OEMs it was really difficult sometimes to meet up, but I was able to make some progress with them and at least speak with some of them.

So, overall it had some big advantages and also some disadvantages – you need to make the best out of this time and take our time to do our homework and come out of it even more strongly.

2. What do you think the textile industry does well, and what is the one topic you believe the industry is struggling with?

This industry is massive, so this is the first thing you recognize once you join this kind of company, in particular Loepfe, because you are engaging with so many different aspects of textiles which all are made for just one purpose and this is in particular equipping mankind – but also ourselves for example as consumers, but also the industries such as automotive – airbags - also face masks that we need to use these days to protect ourselves.

So, lots of our sensors are about safety and, from that point of view, I would say that this industry - with all its history and a lot of the technology - is quite mature in a way, however, on the other hand there’s still a lot of space for example when it comes to sustainability, there’s quite a bit to be done and, when it comes to digitalization, using all this data, kilometers of yarn and these many square kilometers of textiles – thousands, millions – so all of this needs to be traced in a suitable way and data can be used for the future. So, all of this comes together with a lot of technological advantages on the sensor side - and I think on that side we can still do quite a lot in this industry with Loepfe products.

3. What do you believe to be the biggest challenges that our industry will face during the coming years?

The challenges are two-fold. Firstly, players who wish to remain relevant in the future will need to explore the new opportunities that technology provides, as I just mentioned.

Secondly, we are coming out of a double crisis of lowered industrial investment in 2019, followed by the unprecedented collapse in textile consumption during 2020, and we will be confronted with political, economical and ecological shifts that include, amongst other things, the tensions between China and the US, as well as overcapacities in some places.

So, the successful companies of the future in this sector will be those who can align with these shifts, while grasping new opportunities at the same time. I anticipate that this will need to happen really, really fast – the global market won’t wait for the slow-movers.

4. There’s a lot going on in the textile industry: digitalization, sustainability, the circular-fashion approach, traceability and much more. How do you see the role of Loepfe in this situation?

Well, there’s a super-simple answer to this question: Loepfe will and must drive trends and technology in all these areas. In other words, we are reinventing Loepfe today – at an enormous speed – and we are not wasting a single moment when doing so.

As we are now working at full speed on product and digitalization projects – for example even with start-ups – I expect to learn from our partners and exceed our own expectations in terms of transformation speed. While this can be a delicate balance, I am 100% sure that we cannot – and must not – compromise on this aspect.

5. Would you tell us in your own words about Loepfe’s vision and mission?

Vision and mission require the full alignment between a few groups of stakeholders, including our staff. As you know, Martina, we have just set up and reviewed our very first set of purpose, vision, mission and values statements in our 65-year history. Actually, I really had a great experience doing this, as I got so much unexpected feedback all the way from Accounting to IT and Sales & Support. Combined with an agreed set of leadership qualities, we will finalize this to become the foundation of our strategy and operations.

However, I can already state this much with absolute certainty: we will continue to commit to our technology and quality leadership, we will add digitalization and the connected future to our core, and we promise that our sensors will be at the heart of protecting resources and driving a sustainable business – also outside our established markets.

6. The company just turned 65 years. What is your approach to keeping the company successful for the coming decades?

Happy birthday Loepfe! Our future success will need the best professionals in our company. They will listen to customers, develop and offer unique solutions, and produce profits for our shareholders and as a basis for our future. Thus a key step to success is attracting and securing talents and specialists to work with us – for example – in our currently ongoing recruitment of software developers and electronic technicians.

7. Loepfe has a large and loyal customer base. Why do customers rely on Loepfe, and what can customers look forward to in the future?

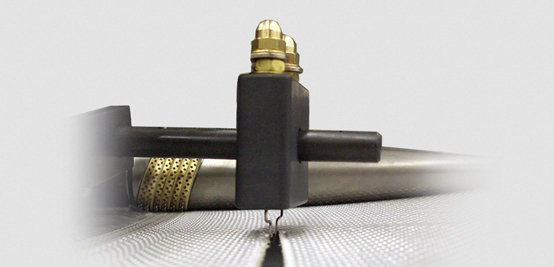

Our customers with spinning and weaving applications got to know Loepfe’s products for their reliability, quality and, in particular also, Loepfe’s spearheading of optical sensors. And they know Loepfe for our global reach when it comes to customer support.

We will further improve on those aspects, for example with our YarnMaster Prisma and EOS, and our WeftMaster Falcon-i, while at the same time we will further increase our technology portfolio, our focus on addressing applications, on adding profitability and productivity to future clients – and all this in a sustainable way.

8. People make companies – what has most impressed you about Loepfe employees?

That’s easy: the readiness and willingness to overcome this crisis together.

9. What is your advice to the company’s clients and stakeholders during these difficult and unusual times?

To them all, I would say: hang in there and see what Loepfe is up to! And, if you haven’t already done so, please share your ideas and feedback with us now, so we can come out of this crisis stronger together – with a real drive and a clear direction for the years to come.

10. As our CEO, you have a lot of responsibility. How do you personally deal with the challenges and the pressure that goes along with these?

You must know by now that I am doing this with complete passion! I signed up with Loepfe to succeed and tackle the challenges together with you, Martina, your colleagues and our business partners. And it’s a real advantage to have such excellent and positive people around me. This is a shared journey and one which, as we succeed together and achieve new goals, we will all continue to enjoy.

11. Finally, what are your aspirations for the upcoming holidays and the New Year?

Well, first of all, I wish all of us some rest, some relaxation time to not think too much about Covid and be with our loved ones. And I think the New Year’s going to bring us a lot of challenges, it’s going to bring changes and, most importantly – for us – some opportunities to take to come out of the crisis and strengthen even more vigorously.