#Spinning

Retech invests in continuous innovation

The Swiss company is the world leader in technology and components for the heat treatment of synthetic fibers, and the latest investments are aimed at strengthening its position through future progress.

Construction work on the new logistics center, at Retech’s headquarters in Meisterschwanden, started at the end of February, shortly before the coronavirus pandemic outbreak. The building was officially opened in mid-July, allowing optimization of production workflows, assembly and quality assurance, with streamlining of both goods-inward and shipping procedures.

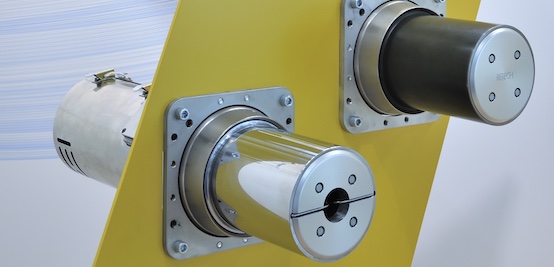

The expansion also took in a complete renewal of the technical center and test laboratory, extending the capability for long-term trials of new developments in area of heated godets, high-temperature applications, temperature regulation and temperature transmission systems. This is a key aspect of Retech’s innovative policy, which has already seen various successful trials and tests on these systems in recent months.

Further investments for this product group have already been made in the winding department for the manufacture of induction heaters. Newest-available technologies are also now in place to ensure optimized and safe production in high-temperature applications.

The combination of significant investment and comprehensive optimization of facilities is evidence of Retech’s commitment to long-term growth and ongoing global eminence in synthetic fiber technologies.