#Spinning

Quality Control made easy

Real-time indication of quality variations

Monitoring system eases quality control at GRG Cotspin

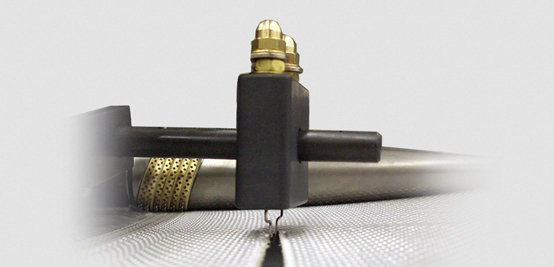

GRG Cotspin, which has been founded in 2013 in Dehli, India, is operating a spinning mill in Anjar in the Indian state of Gujarat. Some 750 employees produce carded and combed cotton and Tencel blend yarns with count range Ne 9-30. Main customer is Welspun, India, a share of their weaving yarns also get exported mainly to the Bangladesh market. GRG´s mission is to manufacture products comparable to international standards, to be customer-focused and globally competitive through better quality, latest technology, and continuous innovation. Therefore the new spinning mill has been equipped with state-of-the-art machinery. In the winding department there are 22 Schlafhorst AC6 Link winders with YarnMaster ZENIT+ yarn clearers from Loepfe. Due to the large portfolio of produced yarns, quality control is quite challenging, as Dilip Kulkarni, Vice President at GRG Cotspin, explains: “It was very difficult after starting the unit working with different yarn counts and clearer settings as per their set standards.” And Mr. Prosanta Sarkar, Quality Control Manager, complements: “To find any changes in clearer settings made by mistake, is time consuming and requires a lengthy process after checking each and every winding machine.” Yarn, which has been produced with wrong clearer settings, can´t be segregated immediately to avoid major loss in quality that can lead to complaints.

MillMaster TOP offers new transparency

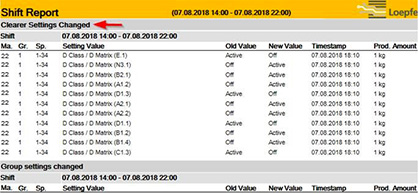

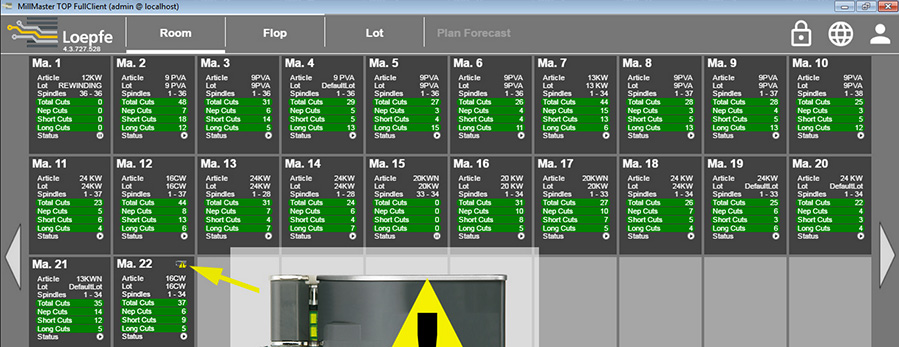

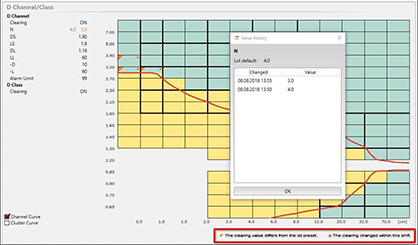

To overcome the above-mentioned challenges, the management of GRG Cotspin decided to utilize the features of Loepfe´s MillMaster TOP. The innovative quality monitoring system delivers online data from all connected yarn clearers in real-time. The system can be used to automatically generate reports, which indicate all changes to yarn clearer settings. Accidentally changed setting can be localized immediately and corrected, before costly errors in yarn quality can occur. A first indication for a change is already signalized in the room view. An icon on the respective machine or machine group calls the attention of the user. A click on the icon automatically opens the relevant shift book, which contains all changes to the settings together with a time stamp. The user can easily review, when the change has been made and how much yarn has been wound since the change. The shift book contains all changes, which have been done during the last four days. In addition, all yarn clearer settings are stored in the shift reports for later review. The graphical presentation of the yarn clearing results contains also an indication of changed clearing values and of differences between the actual settings and the presets for the production lot.

Changes in clearer setting can result as a fault by the personnel, but they can also originate from tests of new setting, which have been performed on a single machine. If the new settings are appropriate, they have to be transferred to all other machines, which are currently producing the same lot. MillMaster TOP makes this task, which has been time consuming in the past, very easy: With a few clicks the new settings are copied to all YarnMaster ZENIT+ yarn clearers – production can continue immediately, and rejections are minimized.

Many beneficial functions

Monitoring of all parameter changes in MillMaster TOP is one of the key functions for GRG Cotspin. With the help of the data filter, the quality control personnel are able to select data from previous shifts, day or a specific time. The reports help to analyze, how clearer settings affect the yarn quality and the winding production. “Overall, we benefit from the various functions of MillMaster TOP, which enable us, to better control and monitor our yarn clearer system”, summarizes Mr. Dilip Kulkarni.

Functionality: MillMaster TOP

The MillMaster TOP online data management system monitors and analyses the quality data from Loepfe yarn clearers, and provides online data from connected yarn clearers in real-time. The modern software can visualise and analyse quality data from up to 7,200 spindles. The data management system has a comprehensive functionality. Data from all winders are recorded automatically. The room view gives an overview for all winding machines. Different colors and symbols indicate the performance of the different machines or yarn production lots. The performance criteria and thresholds can be set individually. A double-click on a machine or a production lot opens a dashboard view with detailed data. There the user can access all quality data in one view. Setting-up MillMaster TOP is very easy. All connected machines are recognised automatically, and afterwards all data is available immediately. With its modern client server architecture the system is the ideal solution for winding machines. The data is not only available on the server, but can also be displayed on various workstations simultaneously. MillMaster TOP can be individually customized with various options, which are installed automatically via Loepfe´s cloud service.