#Research & Development

Medical textiles with infection protection

AGXX technology is based on an entirely new mechanism of action. It uses a catalytic redox reaction initiated by metallic AGXX particles consisting of silver and ruthenium. In interaction with humidity, reactive oxygen species such as peroxides are formed. These are oxygen-containing molecules with very high reactivity. They effectively kill microorganisms such as bacteria, fungi and algae and are equally effective against viruses.

The special feature of this mechanism of action is that the AGXX particles are not reduced and do not release any active ingredients. In established antimicrobial systems based on the release of silver ions, the release of active ingredients has become a problem: the release of the silver ion concentration is difficult to control and many of the established systems do not meet the requirements of the European Chemicals Agency (ECHA). Such systems will disappear from the market in the medium term and must be replaced by alternatives.

In addition to permanent efficacy, the AGXX technology offers a particularly broad spectrum of protection against pathogens and prevents the formation of resistance.

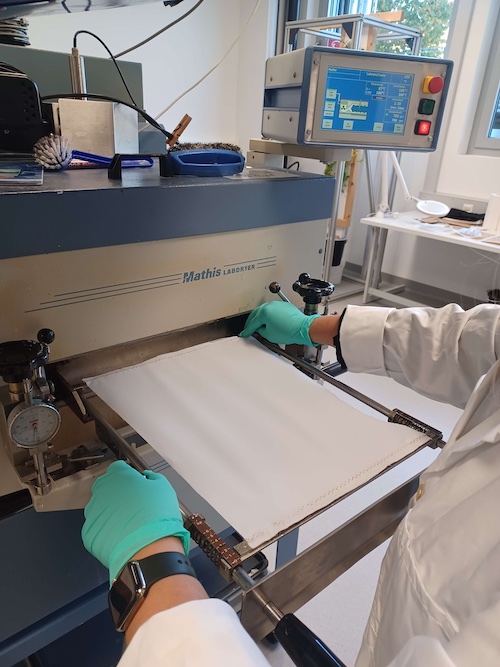

Heraeus AGXX technology has reached a high level of development and is used in various industries. In general, AGXX particles can be easily incorporated into various materials. However, textiles used in the medical sector are subject to more stringent requirements. The resistance of the antimicrobial protection mechanism must be high, as contaminated textiles can be a source of transmission of pathogens over a long period of time. Modification of the textile material, either by surface treatment (finishing or coating) or by incorporation of AGXX into filament yarns, should not adversely affect the physiology of the garment. This is because a reduction in textile properties is unlikely to be accepted by the wearers of the textiles

The integration of AGXX particles into textile finishes and fiber spinnable polymers is the focus of the joint research approach of the DITF and Heraeus. The goal is not only to determine the optimal concentration of AGXX particles to provide the best possible protection against infection without compromising the mechanical properties of the textiles. The technical prerequisites for the development of suitable textile finishes and the compounding of polymer melts are also being created.

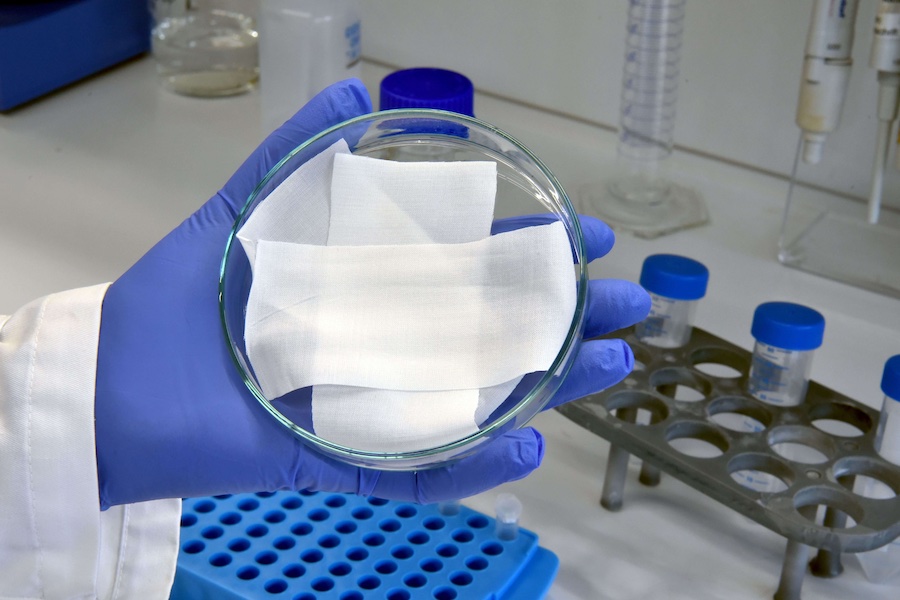

The resulting textile samples are tested for antimicrobial and antiviral activity in the DITF's own laboratories. Here, finishes and coatings for polyester and polyamide fabrics showed convincing results. The compounding of AGXX in the PA6 polymer melt enabled the production of filament fibers with consistently good fiber strength values.

The determination of textile mechanical parameters such as abrasion resistance, air permeability and dimensional change as a function of number of wash cycles is still in progress. However, it is becoming apparent that textiles modified with AGXX are consistently effective without having an excessive impact on the nature of the textile.

The results of the research are an important contribution to reducing the risk of infection from medical workwear. They form the basis for future industrial production of textiles for durable and reliable protection against infection.