#Research & Development

Lavender cultivation on the Swabian Alb: essential oil and textiles from plant residues

At the company naturamus at the foot of the Swabian Alb, there is a high demand for high-quality essential oils for medicines and natural cosmetics. There is much to be said for growing lavender locally. The ecological cultivation of the lavender fields would help to increase the proportion of organic farming in the country and save transport costs.

The cultivation of lavender on the Alb means breaking new ground. The University of Hohenheim is therefore testing five different varieties at four locations, for example at Sonnenhof near Bad Boll. Initial results are expected at the end of the year.

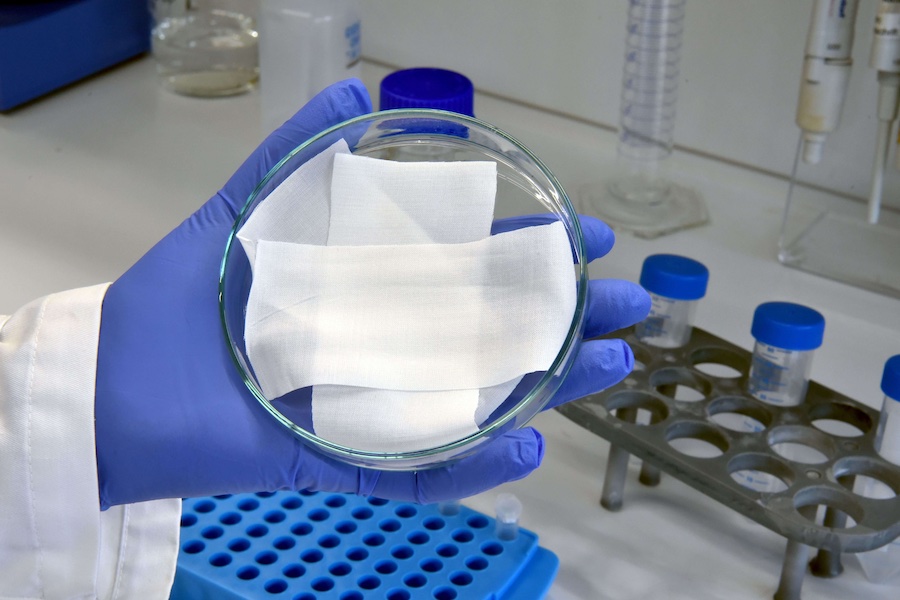

During the extraction of the essential oils, a large amount of residual material is produced that has not yet been utilized. Fibers for textiles can be obtained from the lavender stalk. Developments and analyses with this renewable raw material are already underway at the DITF. In order to utilize lavender distillation residues, the plant stalks with their fiber bundles must be broken down, i.e., separated into their components. Within a fiber bundle, the lignified individual fibers are firmly bound together by plant sugar, pectin. This connection is to be dissolved, for example, with bacteria or with enzymes.

DITF scientist Jamal Sarsour is investigating various preparation techniques and methods to produce long and short fibers from the material. "We are curious to see how high the yield of fibers will be and what properties these fibers will have." Project manager Thomas Stegmaier adds, "The length, fineness as well as the strength of the fiber bundles determine the possible uses. Fine fibers are suitable for clothing, coarser fiber bundles for technical applications."

The chances on the market are good. Regional value creation and ecologically and fairly produced textiles are in vogue. This is not primarily about clothing, but about technical textiles. The fiber composites that are so important for lightweight construction can already also be produced with renewable natural fibers, such as hemp or flax. Even hops fermentation residues have already been used to produce fiber composites at the DITF. Lavender residues could be another natural component for high-tech applications.