#Spinning

TC 30i and IDF 3: Dream Team for direct spinning

The Italian company Marchi & Fildi, headquartered in Biella, was one of the first to test the new IDF 3. The company specializes in producing pure and blended yarns made from natural or man-made fibers for flat knitting, circular knitting and weaving. Its products are used for fashion, furnishings and technical applications worldwide. It also places a strong focus on reducing its environmental impact.

Marchi & Fildi is a pioneer in innovative and sustainable yarns made from recycled materials, with deep expertise in mechanical recycling. Guido Marchetto, Production Supervisor, reports with enthusiasm: "We are very pleased with the new IDF 3. It increases our efficiency and provides higher yarn quality. The ease of operation simplifies the production process. We look forward to the benefits that the IDF 3 will bring to our business in the future". Marchi & Fildi’s first trials were carried out with different fiber blends. This included a blend of 70 % soft waste cotton and 30 % polyester as the raw material for rotor direct spinning, with a yarn count in a range of Ne 8 to Ne 12 and Ne 30.

Remarkable recycling results

Later tests involved fiber blends of 50 % PET and 50 % recycled cotton from hard textile waste for rotor direct spinning with a yarn count of Ne 30. Experts at Marchi & Fildi stated that this material blend is typically very challenging. Processing secondary fibers made from hard textile waste requires very high competence in yarn production, which Marchi & Fildi impressively demonstrates. It also requires advanced technologies. This is due to technological challenges such as significantly lower fiber length. Trützschler’s IDF technology has a special drafting zone geometry that ensures reliable fiber guidance and controls floating fibers. It generates lower drafts than a conventional draw frame passage and avoids the risk of false drafts and count variations.

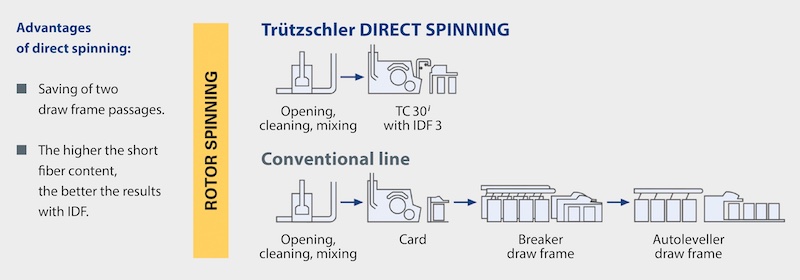

Decades of experience with the IDF technology have demonstrated that the higher the short fiber content, the better the result with IDF compared to conventional two draw frame passages. In combination with the TC 30Ri, a variant of TC 30i that has been specifically equipped and configured for processing recycled fibers, the IDF 3 delivers maximum possible quality for the production of sustainable yarns.

Marchi & Fildi confirmed that combining the TC 30Ri and IDF 3 went beyond their expectations due to the unique possibility of optimizing the process parameters. The TC 30Ri delivers the material at a higher speed and the IDF 3 keeps up with this speed to produce very good sliver evenness – even during the can change. Better sliver quality results in very good yarn parameters that exceed the mill standard.

Overall, the company’s results showed a 75 % increase in productivity over the previous card model and a 14 % reduction in energy consumption at higher production rates. Combining the TC 30Ri and IDF 3 also enabled Marchi & Fildi to skip the drawing stage from its process, which boosts quality while saving resources and cutting costs.

“We have collaborated with Trützschler for many years because its machines offer excellent performance for processing recycled yarns,” says Guido Marchetto. “The machines are easy to set up and adapt for our specific needs. And we can always rely on the effective service support from Trützschler too.”

In conclusion, it’s no surprise that Trützschler’s IDF technology is getting more and more popular across markets worldwide. It makes it possible to significantly shorten the spinning preparation process without compromising on quality. In fact, IDF technology helps to improve quality levels when processing raw materials with a high short fiber content. It also enables shortened processes that save resources, energy and production space. When used together, the TC 30i and the IDF 3 help customers reach the full potential of the direct spinning process.

Benefits of the IDF 3:

• Higher yarn quality and homogenous slivers through advanced measuring devices.

• Increased efficiency by 3 % through new can changing principle that minimizes can change times.

• Easy accessibility for optimal machine handling.