#Recycling / Circular Economy

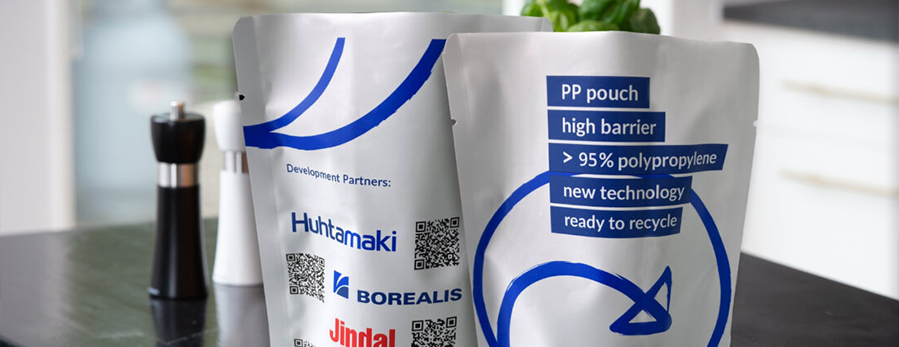

Borealis showcases a new PP monomaterial pouch that is fully compatible for mechanical recycling of Polypropylene at prse 2023

As a monomaterial PP packaging format, it can help meet ambitious recycling and waste reduction targets set forth in the EU’s Packaging and Packaging Waste Regulation (PPWR) as well as eco-modulation criteria for Extended Producer Responsibility (EPR) programmes.

Accelerating plastics circularity through value chain co-operation

High barrier packaging is used to preserve and protect foodstuffs that are sensitive to moisture, oxygen, aromas, and light, like dry ingredients and powders, coffee, and snack foods. Producers and consumers benefit from the longer shelf life and reduced food waste made possible by these convenient high barrier pouches. In the extrusion lamination process, laminating PP cast and BOPP (biaxially oriented polypropylene) films yields mono PP laminates with uniquely advantageous properties. These include high barrier and stiffness, and excellent sealing performance.

Using conventional adhesion lamination structures, producers have previously been able to obtain pouch laminate materials containing approximately 90% PP. However, by pooling their respective areas of expertise, Borealis and value chain partners have now been able to boost the share of PP to over 95%. When processed within dedicated mechanical recycling streams for PP, this monomaterial pouch yields greater volumes of high-quality recyclate fit for use in non-food, flexible PP packaging applications. It is thus the ideal format with which to fulfil the principle aims of the PPWR: improve recyclability, grow the market for recycled content, and reduce packaging waste.

While eco-modulated EPR fees based on packaging recyclability credentials and recycled content may differ among EU Member States, the new monomaterial pouch made of over 95% PP meets the CEFLEX (Circular Economy for Flexible Packaging) definition of “fully compatible to mechanical recycling PP.” It is thus a cost-saving alternative to conventional pouch formats composed of a greater number of different materials.

“In re-inventing essentials for sustainable living, our aim is to uphold the integrity and quality of packaging materials while ensuring that these convenient formats are more and more circular,” says Peter Voortmans, Borealis Global Commercial Director Consumer Products. “We are very proud of this value chain collaboration. It equips our partners and customers with yet another viable and more sustainable solution to help manage the updated requirements of the PPWR.”

The high barrier pouch made of over 95% PP demonstrates excellent seal strength and hermetic sealing properties thanks to the material solutions and production expertise contributed by each of the value chain partners involved in this project. Commercially available polyolefins in the Borealis PP extrusion coating and lamination grade portfolio offer stable processability and good laminate bond strength. These were used in tandem with tie layers contributed by the Mitsui Chemical Group, a leading international manufacturer of specialty chemicals, including polyolefin-based tie resins. As a global leader in the development and manufacture of specialty BOPP films, Jindal Filmscontributed to this innovative solution for recyclable packaging. With locations in Europe, America, and China, Profol, known for its innovative cast PP films and lightweight composites, produced the cast films. Based in Finland and operating in 38 countries, Huhtamaki Flexible Packaging provides solutions that enhance wellbeing and convenience for consumers around the world, and contributed innovative laminates to the new monomaterial pouch.

Please visit Borealis at Hall 12, Stand G22 at the PRSE 2023 in Amsterdam from 10–11 May 2023.