#Recycling / Circular Economy

Converting wastewater into bio-based polymer, essential oils, phenolic extracts and clean water: The AFTERLIFE project presents its results.

In the AFTERLIFE project, a research team of 14 project partners from seven European countries successfully demonstrated a new way of wastewater treatment that simultaneously recovers compounds of interest while converting the remaining organic matter into a high-volume added value bio-based polymer. The project started in September 2017, coordinated by Dr. María López from IDENER (Spain), and ended in February 2022.

AFTERLIFE Pilot Plants

The AFTERLIFE pilot plants have been deployed at BBEU premises in Belgium. The project consortium validated the technology at technology readiness level (TRL) 5. The BBEU team developed and operated four pilot lines for the processing of the following four wastewaters included in AFTERLIFE:

- Wastewaters from the confectionery industry

- Wastewaters from cheese manufacturing

- Wastewater from citric fruit processing – fruit juice line (“JL”)

- Wastewater from citric fruit processing – essential oils (“EO”) line.

The treatment capacity of the operated pilots was one cubic metre of wastewater per day. The different pilot lines were operated sequentially and stopped at the end of August 2021. Essential oils and phenolic extracts production were comparable at lab and pilot scale. The pilot provided oils and extracts that could be tested in food products. The filtration step of all the wastewaters showed good results. For PHA (polyhydroxyalkanoates) production, different alternatives were tested. These included the use of different types of bacterial cultures (pure and mixed cultures) and operation times. The results indicate the necessity of a fine control system in order to achieve a stable PHA production.

AFTERLIFE End Products

Two main groups of products were obtained in AFTERLIFE:

1. Food

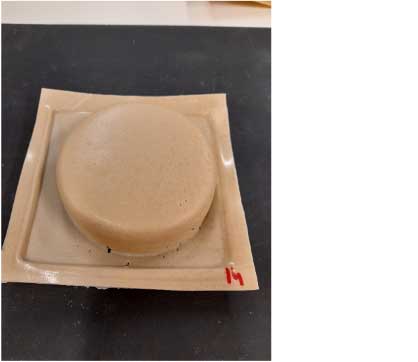

2. PHA-based plastic trays for food packaging

Essential Oils and Phenolic Extracts

Essential oils and phenolic extracts were produced by CELABOR (Belgium) and tested by CTNC (Spain) in food products, including:

- Smoothies

- Mayonnaise

- Green olives

- Fresh meat

- Lettuce gazpacho

- Olive tapenade

For each product, the team evaluated the antimicrobial, antioxidant and organoleptic properties. According to the produced results, essential oils can be useful to preserve the microbiological quality of mayonnaise and the addition of flavonoids extract had antioxidant activity in, e.g., olive tapenade.

Production of PHA-based materials

Socio-economic impacts of the AFTERLIFE technology

The nova-Institute (Germany) performed an analysis of the socio-economic impacts of the AFTERLIFE process and products. The aim was to identify social perceptions and possible socio-economic and policy pitfalls at an early stage of the development in order to guide the process design optimisation. Led by Svenja Dahl, the team came to the following conclusions:

Driver of the AFTERLIFE process: Efficient use of resources and water and non-affiliation with the food versus feedstock debate

Water scarcity leads to a high potential interest of important stakeholders.

Favourable regulatory framework: PHA production, especially the PHA products considered by the AFTERLIFE project, is not handled differently in EU policy depending on its feedstock.

A drawback is that AFTERLIFE’s PHA products and applications have currently no specific support or favouritism in the regulatory framework of plastics. The reason for that is that bio-plastics or bio-degradable as well as compostable plastics have not been specifically excluded or preferred.

The EC is working on a new framework for biobased, biodegradable and compostable plastics that is set to address these issues and provide a clear and well evaluated supportive framework for these plastics (including PHA) in comparison to fossil-based plastics.

The construction of a biorefinery plant offers various benefits to the region such as regional development and smart use of local infrastructure. But the biorefinery wastewater market is still unstable and products have a high fixed cost due to investments and research.

Social Acceptance

Focus groups with randomized end users provided interesting information about consumer views on the AFTERLIFE process and PHA products:

None of the participants had concerns about food contact of wastewater-derived PHA. The risk of possible non-acceptance due to food contact of bioplastic trays could therefore be neglected.

The resource savings through wastewater-derived PHA were considered the greatest strength.

The end-of-life of the products was very important to the participants: Many indicated that they would not pay the Green Premium price for SUP (single use plastic) cutlery if it was not biodegradable or compostable.

There was very little awareness of the production routes of plastics and that different sorts of plastics exist. The participants were sceptical about the advantages of bio-based plastics.

The full social and socio-economic analysis and other public AFTERLIFE project results can be found here: http://www.afterlife-project.eu/results

Funding

The AFTERLIFE project received funding from the Bio-based Industries Joint Undertaking (JU) under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 745737. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and the Bio-based Industries Consortium.