#Recycling / Circular Economy

ISKO joins the Ellen MacArthur Foundation’s Jeans Redesign project as part of its commitment to the circular economy.

ISKO meets the requirements for participation set by The Jeans Redesign guidelines and has made a commitment that 85% of its entire fabric production will consist of recycled material content made from pre-consumer and post-consumer recycled materials. This production will be independently verified by Textile Exchange audit bodies.

This achievement is made possible using ISKO’s R-TWOTM technology which is created through a patented and exclusive yarn spinning technique that retains the unique properties and benefits found in ISKO’s statement fabrics.

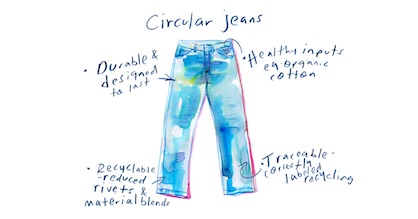

ISKO’s R-TWOTM is the embodiment of its Responsible InnovationTM mindset and aligns with the principles of a circular economy espoused by the Ellen MacArthur Foundation – to ensure durability, material health, recyclability and traceability. R-TWOTM positions ISKO as a sustainability leader and enables it to exceed the project guidelines to create denim that is designed to be used more, made to be made again and made from safe and recycled or renewable inputs.

“We are totally dedicated to helping build a sustainable future for the world; it is critical for the industry to work together to bring positive change. Through our Responsible InnovationTM approach and R-TWOTM platform, we consistently work towards creating ways to make denim more circular. Our participation in The Jeans Redesign brings us one step closer to creating a fully circular fashion industry,” says ISKO’s Head of Sustainability, Ebru Özküçük.

These announcements build upon ISKO’s ongoing sustainability leadership. The company recently signed a licensing agreement with research and development company HKRITA for its award-winning, revolutionary Green Machine – a one-of-a-kind technology that fully separates and recycles cotton and polyester blends at scale. The agreement will enable ISKO to improve and commercialise recycling technologies which will eventually enable the company to offer a 100% post-consumer recycling solution to all of its customers.