#Recycling / Circular Economy

Covestro relies on circulating process water

- Research project aims to improve use of process water

- Further development of existing technology targeted

- Covestro supports UN SDGs with water campaign

Globally, water stress will affect approximately 50 percent of the world's population by 2050. That is why Covestro is already taking action today. At the production sites in Krefeld-Uerdingen and Caojing near Shanghai, industrial saline water recovery plants are already in operation that treat and reuse part of the process water from polycarbonate production. Covestro is thus helping to conserve resources.

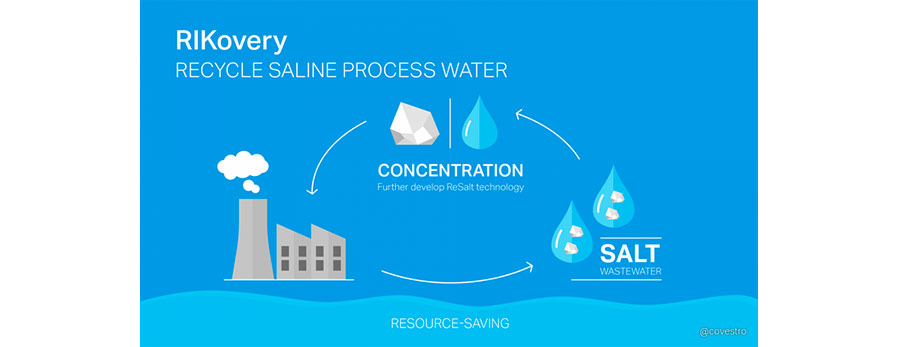

With the RIKovery project, Covestro now wants to take the next technological step to be able to reuse even more process water than before. During the three-year runtime, the project consortium wants to explore how salt-containing industrial water streams can be used as fully as possible to relieve natural water resources.?

Further develop existing process technology

"Strengthening cycles is Covestro's declared goal. We are now taking the next step with RIKovery to use process water in a circular way. The further development of our existing technology shows that the direction is right. Now we need to stay on course to use even less water and salt as raw materials for industrial applications in the long term," says Klaus Schäfer, Chief Technology Officer at Covestro.

In addition to Covestro, other project partners from industry, plant engineering and research are working together. They also include the RWTH Aachen and TH Cologne universities, the Water Technology Center, the Analytical Research Institute for Non-Target Screening (AFIN-TS GmbH), BWS Anlagenbau und Service and Evonik Industries. Chris Malkomes of project partner K+S AG says: "We are pursuing the common vision of using saline industrial water streams by treating them. In addition, the aim is to obtain the most highly concentrated permeate possible from the tailings waters of the potash industry, which can be integrated into existing production cycles and utilized there."

"Forward-looking, efficient industrial water management will become a key factor for safe industrial production in the future," says Thomas Track of DECHEMA, which is coordinating the project accompanying the BMBF funding initiative. "Water-efficient sites are a real locational advantage with a view to resource conservation, but also with a view to droughts favored by climate change."

Covestro supports UN SDGs with internal water initiative

Covestro is aware of the special responsibility that the use of the valuable resource of drinking water entails. For this reason, the Leverkusen-based materials manufacturer has additionally launched an internal initiative to creatively develop proposals for sustainable water use. As part of this campaign, the workforce was called upon to submit ideas with business potential based on the United Nations Sustainable Development Goals (SDGs).

Employees from all regions participated in the water initiative. This resulted in dozens of ideas for innovative solutions around the topic of water. A jury selected more than 20 from all the ideas. These are now being tested at the working level.

Among the suggestions from the workforce, many ideas were generated for urban agriculture, but also for cleaning water of microplastics. A major role was also played by the company's own water consumption in production and how this can be improved.

If the ideas prove to be effective and feasible, they will be introduced on a large scale. In this way, Covestro is helping to protect the important resource of drinking water even better in the future.