#Raw Materials

Marketing Cotton: Challenges and opportunities

He also presented some solutions developed by Cotton Inc – an idea company focused on the mission of advancing demand for cotton.

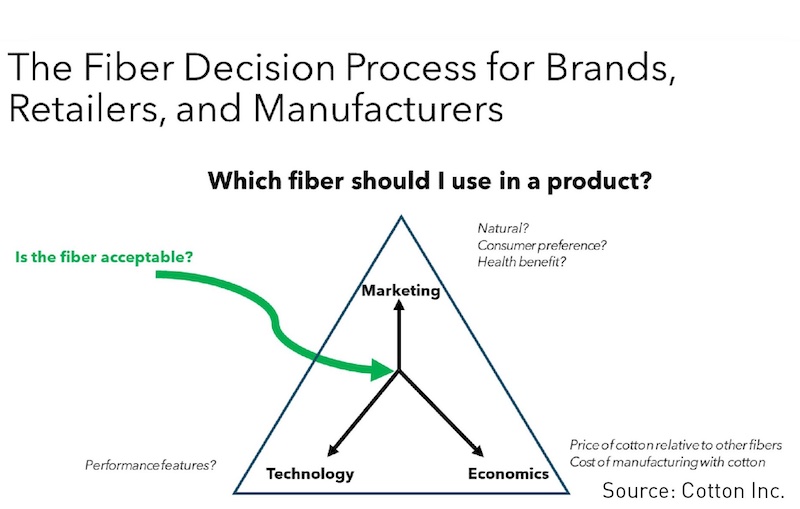

The Marketing Triangle

Brands and retailers face a marketing triangle, with the sides composed of marketing, technology and economics. Cotton must have a competitive advantage in at least one of the areas. In marketing, cotton may have an advantage because of consumer preferences, or health benefits. Cotton is currently at a strong economic disadvantage to polyester. Technical applications can expand the range of uses for cotton and improve cotton’s technical performance capabilities. Functions such as water repellency, moisture management, enhanced durability, wrinkle resistance, and stretch are being developed through research by Cotton Incorporated and partner research organizations.

More and more, brands and retailers are asking if a fibre is acceptable. Is it sustainable? Circularity, recycling, and biodegradability are factors companies consider, even before they talk about marketing, economics or technical performance.

Technology can also provide support in this context. Increasingly, consumers are defining sustainability as durability. Tough CottonTM is a new technology that increases abrasion resistance with a dual-process treatment. Another new technology is RESTech CottonTM, a comfortable, durable, sustainable sheeting technology that can compensate for the disadvantages of cotton compared to competing fibers such as viscose or polyester. Cotton has lost market share to rayon from bamboo and polyester. RESTechTM cotton dries 50% faster than rayon, it is temperature regulating and 40% softer than regular cotton, creating a marketing opportunity for cotton.

Sustainable Cotton in a Circular Economy

About 5% of cotton is used in nonwoven products, including diapers, disposable wipes and feminin hygiene products. Cotton Incorporated is working with companies to replace plastic components in diapers, hygiene and health products, including rigid components, with biodegradable cotton.

Circularity is another sustainability concept. Cotton is grown from the earth, and cotton products can be returned to the earth, the best definition of “Circularity.”

Because of the degradation of intrinsic fibre quality through the mechanical recycling of cotton fibres, new uses for recycled cotton must be found. Cotton can be biodegraded into a soil enhancer. Composting cotton has been studied, and a pair of blue jeans is completly degraded after three months, except for the polyester liner and pockets.

Given all the uses of cotton, companies could be using more than they do. However, there is a tremendous amount of misinformation about cotton in the world market. The work of the SEEP panel of ICAC is very important. Retailers and brands are not farmers or experts on cotton, and they need to be given the facts about cotton. There is room in the market for organic, conventional, GMO and non-GMO cottons.

Traceability is a key concept in sustainability discussions today, and polyester must be held to the same standard of traceability as cotton. What factory did the polyester in a product come from? If you want to know the farm where cotton was grown, you need to know the oil well that polyester came from.

You can find Mark Messura‘s presentation on the Bremen Cotton Exchange website: Presentations

https://baumwollboerse.de/en/competencies/international-cotton-conference/vortraege/

canva-900-1-1-1.jpg)

canva-900-1.jpg)