#Raw Materials

Understanding BCI’s traceability journey

Why is traceability important?

Understanding the route Better Cotton takes from field to market enables a clearer view of risks and where to prioritise efforts for continuous improvement. It will build on our existing efforts to build farmers’ capacity to adopt more sustainable practices and promote decent work and will facilitate the inclusion of producers in increasingly regulated international value chains, helping to improve lives and safeguard livelihoods in cotton communities. The sourcing landscape is changing, and we want to make sure these changes are good for those who produce and source Better Cotton.

So what we are doing to make this a reality?

We are currently exploring the best possible options to achieve physically traceable Better Cotton. In the next few months, we will test various traceability solutions and partner with new and existing stakeholders to forge a collective pathway to systemic change. We will also hold workshops and conduct surveys to gather inputs and requirements from our members. To ensure a viable, fit-for-purpose solution, we need to make sure it works for BCI Farmers, and for every actor in the cotton supply chain.

Traceability is a huge investment for BCI, and everyone involved across the supply chain. Funding is needed to develop robust, workable systems, and to help all the relevant actors invest in change. This is particularly important for smaller actors like smallholder farmers and small-scale ginners, who may not have access to the finance and resources to make the changes that are needed. While traceability comes with a cost, it also represents an opportunity to create new and innovative value for BCI Farmers, such as rewarding them for carbon sequestration.

As a starting point, and to help us shape our initial vision, we have created a panel of experts from among our Retailer and Brand Members. This will help to build momentum and determine the best way to engage effectively with all our stakeholders, while providing expert insights, forging relevant connections and generating a consensus over a practical, realistic way forward.

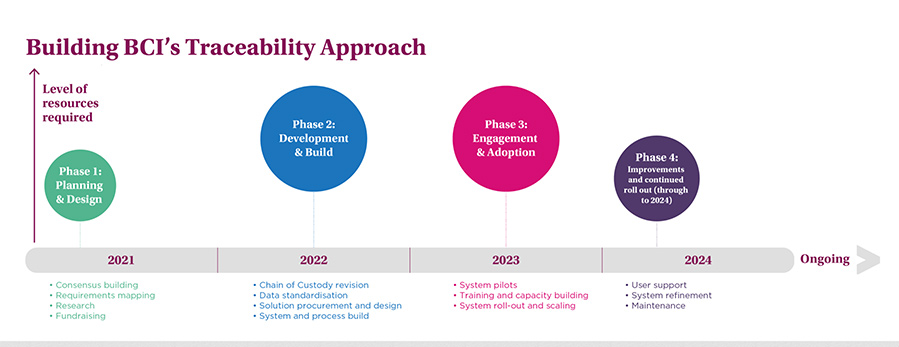

Importantly, we have a clear view of how the project will unfold. Initially, we are collecting input and requirements from our members, while exploring solutions and developing a strategy for implementation, including how the potential solution will be funded and managed, before moving ahead to designing and testing the selected solution. We’ll gradually build engagement with our global BCI community to put it into practice, making any adjustments along the way. Once the solution is established, we will keep monitoring and evaluating its effectiveness, to ensure service quality and continuous improvement.

We’ll keep you informed of our progress, too. In August, we will launch a new series of blogs on traceability to explore why and how the sector is seeking more enhanced traceability and transparency.

For more information on the benefits and challenges of traceability, you can visit this blog post from the end of last year just as this workstream was launching.