Nonwovens / Technical Textiles

ANDRITZ presents new technologies for nonwovens production at Techtextil India

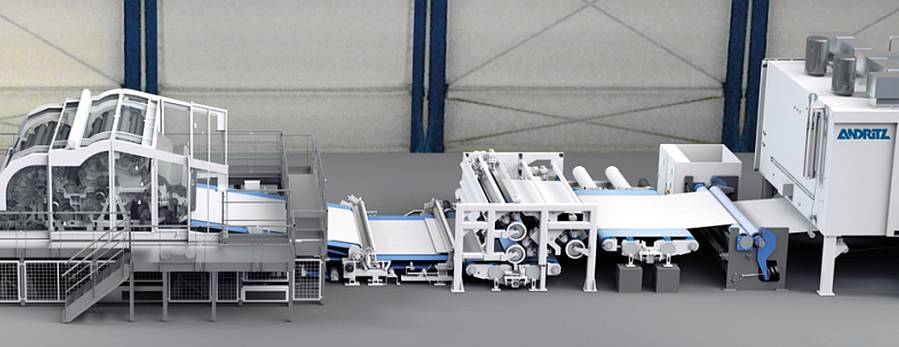

Turnkey spunlace lines with unequalled energy efficiency

Meeting various producers’ needs, ANDRITZ offers spunlace turnkey lines with unequalled energy efficiency ratio and a wide range of solutions. For extraordinary high production performance, ANDRITZ neXline spunlace combines carding system, hydroentanglement, dewatering, through-air dryer, as well as hydro and thermo embossing.

For traditional textile producers who plan to manufacture nonwovens at medium-capacity level in the future, ANDRITZ offers neXline spunlace aXcess. It includes a carding system and the Jetlace Avantage hydroentanglement unit, a proven concept designed to produce lightweight fabrics at low operating costs. For durable products, such as automotive or filtration applications, the Jetlace Evolution hydroentanglement unit is equipped with card and crosslapper and is designed for the production of nonwovens with various mechanical properties.

High production capacity and flexibility in technical textiles as well as innovative technologies for new products from natural and man-made fibers

For manufacture of technical textiles, ANDRITZ has developed an innovative calender concept incorporating proven technologies from the production of paper and nonwovens.

The teXcal trike, a 3-roll calender with two separately controlled system rolls and a closed loop system for inline product quality measurements, provides high production capacity and flexibility in technical textiles.

At Techtextil India, ANDRITZ Nonwoven will also present innovative wetlaid technologies for the development of new products from natural and man-made fibers, such as carbon, micro glass, or aramid.

Needlepunching and through-air bonding production lines: complete process solutions for growth markets automotive, filtration, geotextile, and hygiene

ANDRITZ offers complete process solutions for needling and through-air bonding. These processes are currently in great demand also in the Indian market in order to keep up with growth in the automotive, filtration, geotextile, and hygiene industries.

Pic: New technical center at ANDRITZ Asselin-Thibeau, dedicated to needlepunch Technology

The ANDRITZ eXcelle and aXcess series provide cards, crosslappers, and needlelooms for medium and high production capacities. Both systems, based on European technologies, are assembled at ANDRITZ facilities in China and are available for trials and demonstrations in the ANDRITZ technical centers in Wuxi, China, and Elbeuf, France.