#Nonwovens / Technical Textiles

KARL MAYER Technische Textilien is delighted with the sales success of its MAX GLASS ECO and TM WEFT 2

This year is also starting with positive prospects. “In the first week of January, we already had eight inquiries from potential new customers in China alone about our latest TM WEFT,” says Jan Stahr, Regional Sales Manager of KARL MAYER's Technical Textiles business unit, pleased with the promising start to the year. The concentrated interest is based on an example that has set a precedent: it comes from a Chinese textile region with traditional waterjet weaving mills, where the first two warp knitting machines with weft insertion were installed just a few days before. By switching to TM WEFT 2 technology, the environmental impact of wastewater is significantly reduced, and customers benefit from a considerable increase in efficiency.

The machine is also attracting interest from traditional warp knitting customers looking for new fields of application.

Convince through performance

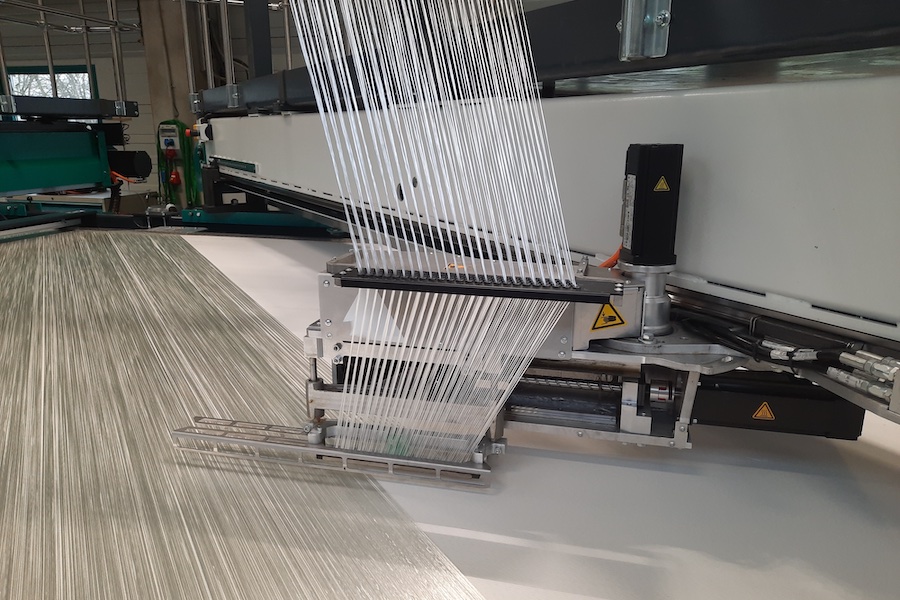

Sales success is based on machines that are precisely tailored to market requirements. The TM WEFT 2 offers not only a general technological advantage over weaving machines, but above all a convincing price-performance ratio, easy operation and an extremely long service life. The warp knitting machine with weft insertion is 20% more performant than its predecessor and has been further developed, particularly in the area of the crankcase system. The technical features also include the proven carbon bar equipment from KARL MAYER and functional optimizations.

With the MAX GLASS ECO, KARL MAYER Technische Textilien offers a reliable production machine for the extremely economical manufacture of standard articles made of glass fibers. In particular, manufacturers of fabrics for the wind power industry benefit from the performance of the sought-after composite machine. Its performance strengths include an extremely high output. At a maximum speed of 1,800 rpm, up to 410 m of fabric/h can be produced at a working width of 101". In addition, the MAX GLASS ECO can be modified with various optional functions to optimally meet the requirements of different applications. All this is available at a price that significantly shortens the amortization period of the economical machine compared to its predecessor.