#Nonwovens / Technical Textiles

HeiQ launches high-tech mask featuring ground-breaking copper technology shown to deactivate the COVID-19 virus in five minutes

Global leader in textile and materials innovation, HeiQ, launches HeiQ MetalliQ, a futuristic-looking, high-tech surgical mask that destroys all viruses and bacteria tested, up to 100% efficacy.

Studies conducted by the Peter Doherty Institute for Infection and Immunity in Melbourne, Australia (Doherty Institute) showed that fabrics treated by the HeiQ MetalliX technology significantly deactivated the infectious SARS-CoV-2 virus (the virus that causes COVID-19) in as little as 5 minutes.

The testing protocol simulated the real-life interaction of aerosol droplets contaminating textile products such as face masks. Each sample was exposed to a high loading of SARS-CoV-2 followed by 5, 15 and 30 minutes incubation at room temperature before the amount of remaining infectious SARS-CoV-2 viruses was measured. The fabric samples treated with HeiQ MetalliX indicated a virus reduction of over 97.79% in five minutes, 99.95% in 15 minutes and over 99.99% in 30 minutes, relative to the inoculum control.

“Our team of experts continue their vital work to minimize the impact of the novel coronavirus.” Dr Julie McAuley, Senior Research Officer at the Doherty Institute, stated. “Testing the ability of different surface treatments to reduce infectivity of the SARS-CoV-2 virus is one way that our research can help provide insights towards helping to stop the spread of COVID-19”, Dr McAuley added.

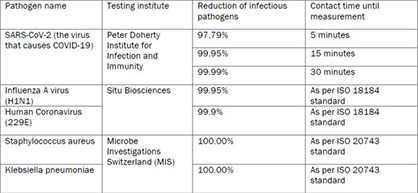

Copper is a naturally occurring element, present in the earth’s crust, soil, oceans, lakes and rivers. It is also a trace element that occurs naturally in all humans, plants and animals. The antiviral, antibacterial and antifungal properties of copper has been known for centuries and have been demonstrated by many laboratory studies. HeiQ MetalliX treated materials release copper ions which deactivate viruses and bacteria. Treated materials have also been tested to kill 100% of Staphylococcus aureus and Klebsiella pneumoniae and deactivate 99.95% of H1N1 virus and 99.9% of Human Coronavirus 229E.

Made in EU, HeiQ MetalliQ is manufactured in HeiQ Medica in Spain where HeiQ also conducts R&D activities for medical devices. Throughout the development of the HeiQ MetalliX technology, Xefco worked closely with long-standing research partner the Institute for Frontier Materials (IFM) at Deakin University as part of the world-class ARC Research Hub for Future Fibres, of which HeiQ is also a member.

“You can pretty much ‘heiq’ everything to add additional functions to an every-day product. This time we up our game once again in antiviral protection, with an upgraded and premium appearance. Spring is calling. As we emerge from lock-down we want to be extra protected and protect the others. HeiQ MetalliQ is designed exactly to provide that extra level of confidence. Further, it gives an edgy look, making it an improved alternative to surgical masks in many ways,” says Carlo Centonze, co-founder and CEO of HeiQ Group.

HeiQ MetalliX efficacy data