#Nonwovens / Technical Textiles

New machine family for the production of high-performance stone bags

The stone bags made from the coarse net structures can be used for a variety of heavy-duty applications. Established applications include shore erosion control, foundation consolidation for bridge piers and disaster recovery structures.

The stone bags made from the coarse net structures can be used for a variety of heavy-duty applications. Established applications include coastal erosion control, foundation consolidation for bridge piers and the construction of disaster defence structures.

When used in demanding environments such as coastal and marine projects, the RMF 8 EL and HDR 9 EL NET stone bags offer unrivalled performance. The main feature here is their large capacity. Depending on the net structure, the bags can hold stones weighing between one and 12 tonnes. Made from recycled polyester or polyethylene fibres, they are also exceptionally strong, durable and adapt flexibly to the ground.

Production with variety and efficiency, products with many advantages

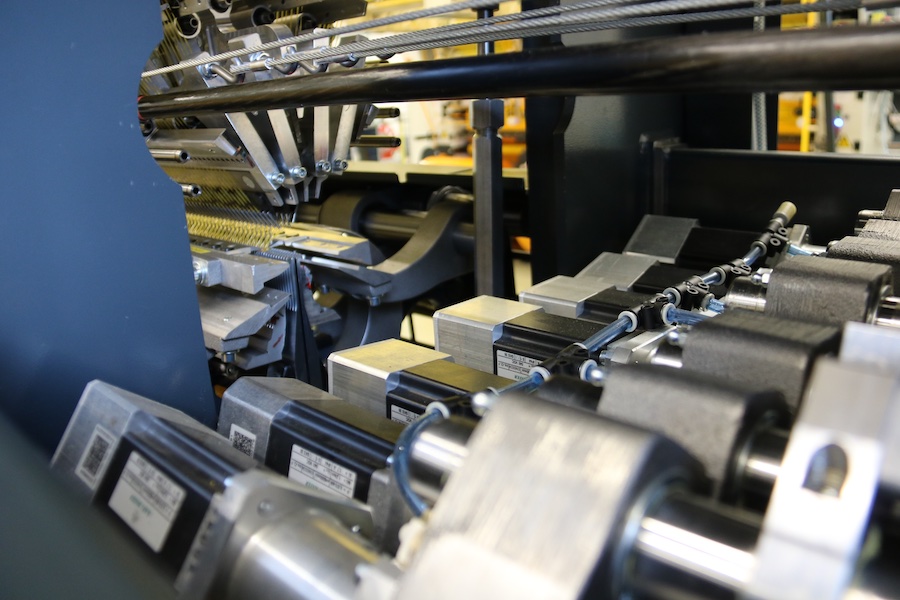

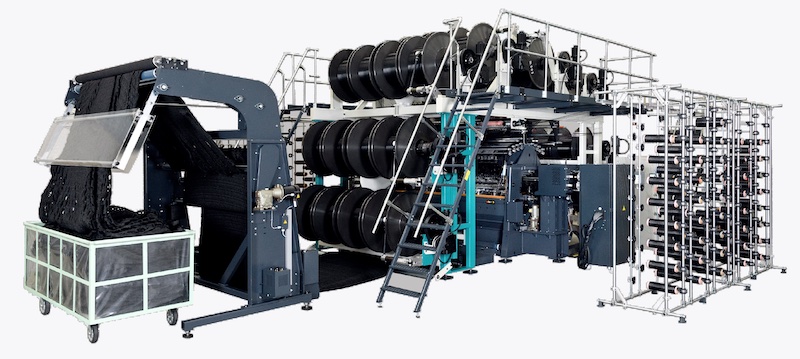

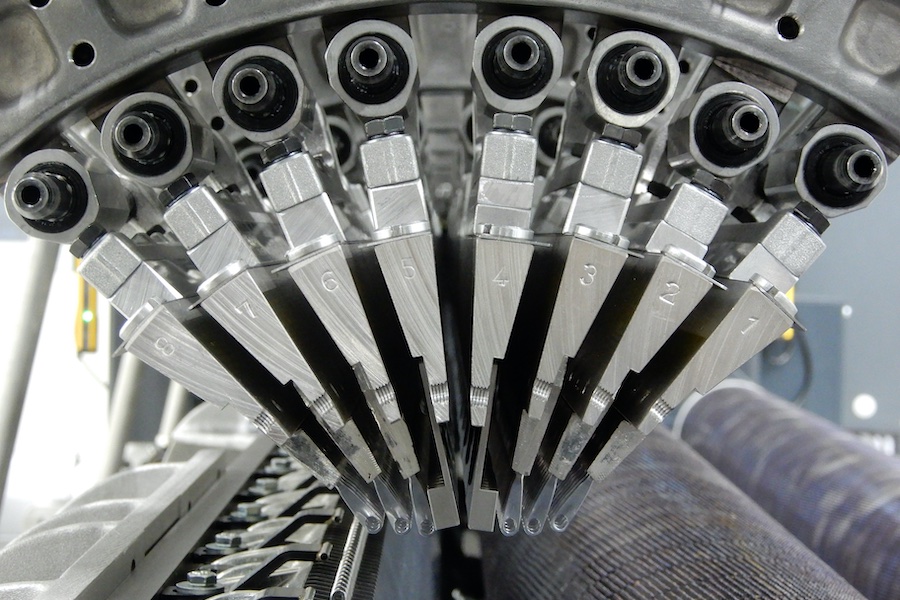

The RMF 8 EL is the machine of choice when it comes to size flexibility. It produces items with a wide range of widths. A maximum of 190" is possible. In addition, different gauges - E3, E4, E8, E9 are available- make it possible to adapt the net structures to the operating conditions in terms of robustness.

The HDR 9 EL NET manufactures ready-to-use articles with two different gauges, E4 and E7, and thus streamlines the production of high-quality, tubular nets. The manufacturing process is extremely fast and cost-effective, with no additional sewing or finishing work.

The warp knitted stone bags themselves offer further advantages. The use of synthetic fibres makes them resistant to rust and corrosion, making them perfect for use in harsh environments, for example under the influence of seawater.

The net products are also extremely flexible. Thanks to their stitch structure, the stone bags made from them can adapt smoothly to uneven surfaces and fill gaps and open spaces effectively. This makes them particularly suitable for use in the construction applications.

The stone bags manufactured by RMF 8 EL and HDR 9 EL NET also score highly in terms of weight and stability. They are lightweight, yet extremely stable and therefore easy to transport, handle, fill and install. Their use on site requires less skilled labour and the installation process is faster. If crane-assisted methods are used for filling and installation, specialised personnel are no longer required.

Two machines, many applications

The RMF 8 EL and HDR 9 EL NET machines can be used to produce nets, mostly for stone bags, which can be customised to meet the various requirements of their industrial applications thanks to different net densities and dimensions. The fields of utilisation are extremely diverse.

Shore Protection: The stone bags can be used for coastal protection projects, for example for the construction of breakwaters, groynes and revetments. They absorb and dissipate the wave energy. This prevents erosion and protects the coastline.

Consolidation of foundations for bridge piers: In river and marine environments, stone bags permanently stabilise and consolidate the foundations of bridge piers to ensure structural integrity in erosion-prone areas.

Disaster Recovery Construction: Following natural disasters, stone bags can be quickly deployed to stabilise damaged infrastructure and prevent further erosion. This makes them a fast and reliable recovery solution.

Foundation work for temporary roads: In situations where temporary roads are needed, especially in soft or unstable terrain, the stone bags can be uses to provide stable foundations, supporting safe passage for heavy machinery and vehicles.