#Knitting & Hosiery

New location, more customer support

In 2020, the KARL MAYER Group acquired STOLL, and in 2021 U.S. operations of the flat knitting machine company were relocated from New York City to the KARL MAYER location in Greensboro, NC. Significant investments were made there in a state-of-the-art development and visitor center, to be used for demonstration of all KARL MAYER technologies, for STOLL knit product prototype development and for training, the TexLab at KARL MAYER North America.

During the STOLL Days from 7 to 10 June 2022, customers and other business partners can get to know the STOLL team, and the fully equipped TexLab, with the latest STOLL machines, other equipment to develop knitted products and multiple collaboration and training areas. For the event, STOLL prepared an exciting program to inspire the innovativeness of customers and others that are interested in the use of flat knitting technology in their products.

Highlights include various STOLL machines in action, including a few models that were not shown before, seminars and workshops to introduce new design and programming software, and many inspiring knitted products for fashion and for technical textile markets. The presence of some yarn suppliers and other industry partners will complete the event.

A wide range of machines

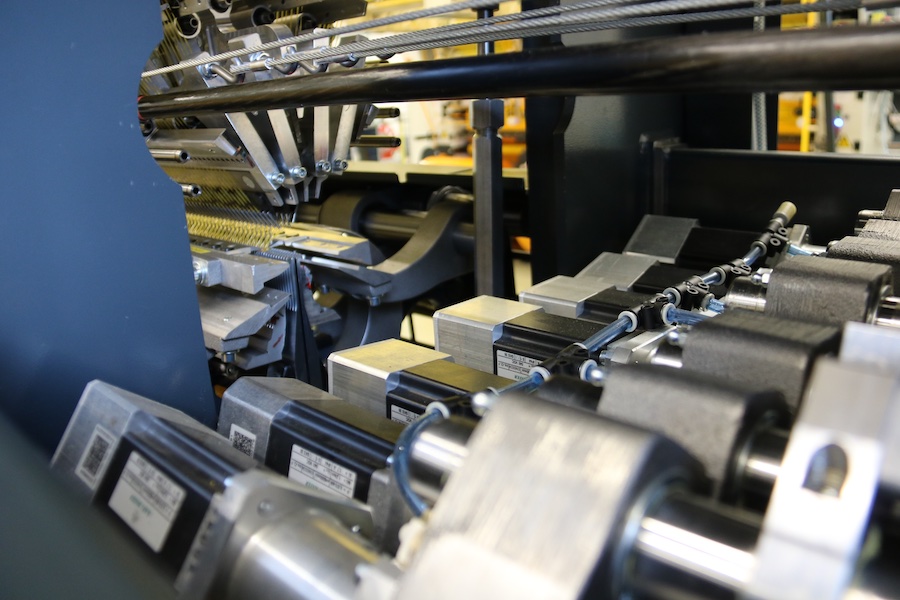

For product development and the transfer of know-how, the TexLab offers a quite complete range of STOLL flat knitting machines. Highlights include the ADF machines with a working width of 50" to 84" for technical textiles and fashion.

The design possibilities of the versatile models with options such as Inverse Plating for double-sided multi-color effects and STOLL-weave-in® for weaving optics with variable yarn use and maximum productivity are almost endless. With STOLL-knitrobotic® even functional components such as nose bridges for masks can be inserted directly into the product during knitting. New to the ADF range is the ultra-fine E10.2-gauge machine. From the CMS family, the CMS 202 with a 24" working width for smaller sized knitted fabrics is an interesting option.

Trends in fashion and technical textiles

An exclusive knitted product hub will show what can be done with the innovative machines.

In an exciting setting, the new STOLL trend collection "Wonderful" will stand out. In addition, technical textiles for the automotive, office furniture, medical and industrial markets will be shown. The promising market of Smart Textiles also has its place during the STOLL Days and results of a cooperation between STOLL and Myant will be shown.

First-hand know-how

The guests in Greensboro can also learn how the potential of the STOLL machines can be exploited. The TexLab serves as a training facility for machine operation, and for STOLL design and programming software. Training is available for the programming software M1plus, its successor software k.innovation CREATE PLUS, and the design software k.innovation CREATE DESIGN.