#Knitting & Hosiery

HKS 3-M ON with maximum operating convenience thanks to intelligent solutions

Bar changing – made easy

Customer-oriented features also reduce the risk of operating errors. One of the most important of these is the Spring Motion Assistant – an automatic return device that makes changing guide bars much easier. The new solution starts with the most labour-intensive part of the process: the handling required for the spring motion and pattern push rod.

Hand-in-hand with the machine

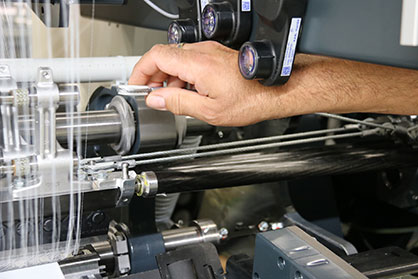

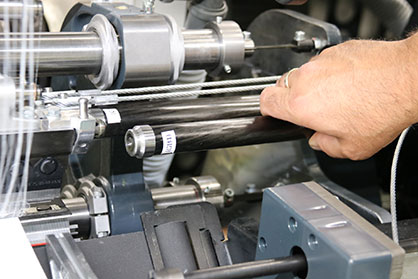

Together with the push rod, the spring motion forms a system that transmits the pattern-specific movement impulse from the electronic pattern drive to the guide bar. One end of it is hooked into a peg on the guide bar as a loop, while the other end leads to a spring unit that is screwed into a sleeve on the drive unit via a bushing. The operator fastens the connection tight and tensions the spring motion using two spanners. This results in highly-precision guide bar movement in line with the requirements of the electronic guide bar drive. This spring motion system needed to be optimised to work with the new ON gear in the HKS 3-M ON, and the developers also took this opportunity to improve it in terms of ease of use. “As part of our work, we adopted a collaborative interaction approach between man and machine,” says product developer Klaus Benno Brandl. When it is time to change the guide bar, the operator is supported effectively by the HKS 3-M ON. There is a special function on the touchscreen that guides them through the partially automated process step by step.

They start by loosening the yarn sheet in the guide bar. Once this is done, the ON gear moves the guide bar and releases the spring motion. The operator then removes the spring motion, swivels the push rod to the side and removes the guide bar. Once the spring motion and push rod are back in their original places with the newly threaded guide bar, the spring motion is set to the correct position and tensioned automatically. The machine lighting visually informs the operator that the function has been completed and production can continue. The Spring Motion Assistant is thus convenient, safe and requires less effort from personnel than the previous system. What’s more, the patented solution does not require any tools. The innovation now comes as standard on the HKS 3-M ON. The first machine with this user-friendly return device was delivered in May 2021.