#Knitting & Hosiery

New tricot machine for the volume market

The new TM 4-S expands KARL MAYER’s range of four-bar tricot machines

A new model has now been added to the wide range of four-bar machines available: the newcomer is called TM 4-S and is with its performance focused on the volume market. Its performance features include an exceptionally high speed – the maximum is 1,800 rpm – and a working width of 280?, which can be further extended by 10?. The TM 4-S therefore offers maximum productivity at an extremely attractive price, and the needle and guide bars were manufactured using proven carbon fibre technology to achieve high temperature stability and low weight.

The new development also relies on tried-and-tested operability and quality. The TM 4-S is extremely easy to handle thanks to KARL MAYER’s well-thought-out man-machine interface and meets the exacting requirements set by the Group of companies.

As with all models in the four-bar product family, the new machine covers an extremely diverse production spectrum. Lightweight silk net and lingerie articles can be converted just as easily and efficiently as raised velour fabrics, shoe fabrics, home textiles or even upholstery fabrics for the automotive sector.

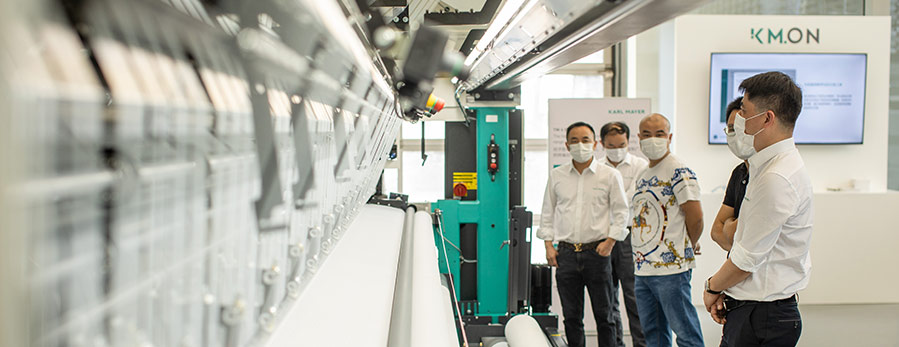

The TM 4-S made its first public appearance as part of an in-house show at KARL MAYER (CHINA), which took place in June 2021 over the course of the ITMA ASIA + CITME. The performance demonstration for this rapid all-rounder was met with great interest here; numerous project meetings were held during the exhibition, thereby generating ideas for how to use the newcomer.

From the third quarter 2021, the TM 4-S will be sold. It is currently available in gauges E 28 and E 32, and the standard equipment includes a 4 x 32? beam frame.