#Knitting & Hosiery

Dissolving design boundaries

4D-KNIT articles in a new gauge offer style, lightness and a soft touch

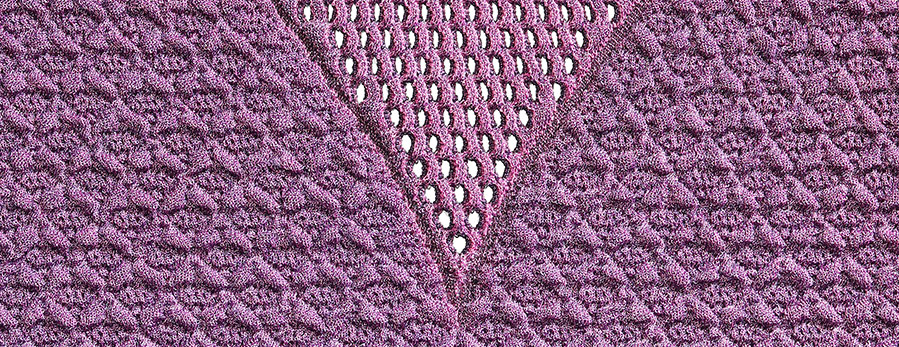

The spacer layer is particularly different: the space between the upper and lower can be filled with bulked yarns to achieve unprecedented effects in performance and design. In addition to a smooth pattern, two-tone colouring and breathable mesh zones as before, the two surfaces can have clearly pronounced relief designs – each with individual placements and dimensions. Depending on the amount of filling and the design of the plastic motifs, a wide variety of pieces is possible, from cosy padded jacket fabrics that keep you nice and warm in winter to breathable textiles for functional shoes, for example. The new warp knitted spacer fabrics are produced on a RDPJ 6/2 EL FB, previously in gauge E 24. To further explore the potential for the sportswear and outerwear sector, KARL MAYER’s textile product developers have produced the first 4D-KNIT products on a jacquard double needle bar raschel machine in E 28.

New expression of fabrics for sports and leisure

Material processed in a gauge of E 28 is commonly used to produce fine elastic sportswear items. Skilfully threaded-in on the machine, the result was a fabric that weighed significantly less than its E 24 counterpart and felt soft to the touch. What’s more, the functional chic design hits just the right mark. With its two jacquard bars, the RDPJ 6/2 EL FB makes the front side and back side of the top as a single piece with fashionable 3-dimentional bulky form – including every sophisticated design detail. These include contours to mark the cut edges, flat bars for segmentation, open mesh parts and underpadded relief patterns with small-format geometric motifs.

The small repeat of high-low effects reduces the fabric’s contact area on the skin and therefore minimises any unpleasant stickiness caused by sweat, while perfect thermoregulation for sport and leisure is ensured by breathable mesh areas with sufficiently large openings, and built-in elastic zones offer freedom of movement. Yuji Yamamoto, Regional Product Owner for double needle bar raschel machines at KARL MAYER, wants to use the new series to appeal primarily to fashion and sportswear manufacturers. “The apparel sector in particular can benefit enormously from these new 4D-KNIT fabrics. The low weight and soft feel guarantee a high level of wear comfort, and the yarn material in the spacing also offers good insulating properties with extremely low discharge of microplastic particles, since we do not use brushing or raising processes,” explains the textile specialist.

You can find more information on the pattern in KARL MAYER’s virtual showroom under:

https://www.karlmayer.com/en/support/textile-consulting/virtual-showroom/smart-and-stylish/