#Knitting & Hosiery

Two brands – one objective: Innovations for the creative process

Synergies between STOLL and KM.ON for the benefit of customers

STOLL and KM.ON – two successful KARL MAYER Group brands – combined their expertise and creativity for the new offering CREATE to maximise the benefits for their customers. STOLL is a pioneer in flat knitting technology and brings unique process knowledge to its business, which results in perfect flat knitting solutions and excellent customer support. KM.ON is an agile specialist in innovative software products, as well as digital solutions and services for the textile industry.

CREATE belongs to the k.innovation category of KM.ON solutions that focus on an accelerated design-to-market workflow.

CREATE’s key features

With a well-thought-out shape and grading tool, CREATE offers the possibility to create shapes and to implement customised adaptations or size adjustments just as easily. An important part of the tool is a shape library with numerous presets.

For the creation of knitted fabrics, an integrated yarn library offers a first selection of standard and fancy yarns, that will be continuously updated. Additionally, there is the possibility to create your own yarns.

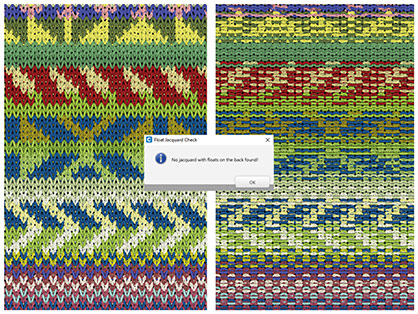

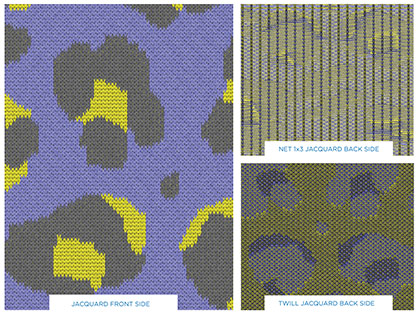

The software includes an extensive library with different stitch constructions that can be used for the design. Additionally, the customer can create own digital stitch constructions with simultaneous stitch simulation and to run technical design checks.

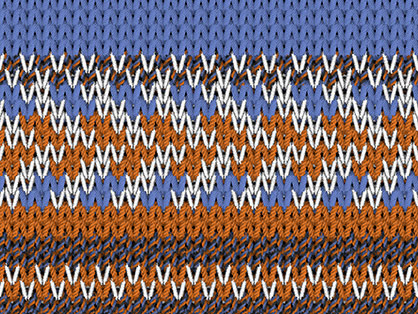

The virtual fabric views have a true-to-life imitation of the stitches and their distortions, which makes it possible to conceptualise and plan a collection with fewer or no physical sample pieces. With a colourway generator, different colour combinations can also be tried out.

Last but not least, the design program can be used as a basis for the knitting programme. Once a technician has completed various checks, the knitting process can then be started immediately.

More information about CREATE will be available on the KARL MAYER Group’s exhibition stand at ITMA ASIA + CITME, 12 to 16 June, A 35/Hall 4 at the NECC Shanghai and also on the STOLL website:

https://www.stoll.com/en/software/kinnovation-create/