#Nonwovens / Technical Textiles

Intensifying talks with the plastics sector

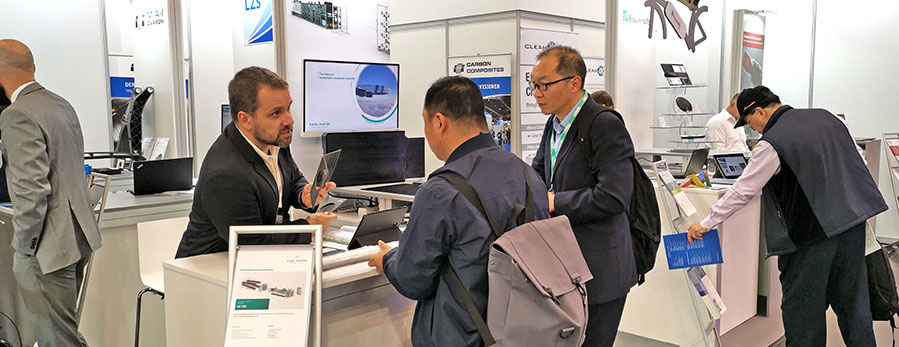

This international event is a leading trade fair for specialists involved in the plastics and rubber sectors, and in the production and processing of plastics. It was held recently from 16 to 23 October 2019 in Düsseldorf. The aim of KARL MAYER Technische Textilien’s participation in K 2019 on the umbrella stand of Composites Germany was to make new contacts among plastics processors, and the company was far from disappointed. Visitor numbers were especially high over the first three days of the fair.

Traditionally, roughly 70% of the visitors travel to the K fair from abroad. And two-thirds of those visiting KARL MAYER Technische Textilien came from outside Germany, mainly from North America and Asia, primarily from China and India.

Many new contacts and a higher profile on the market

To arouse the interest of the visitors to the fair, this company was focusing on presenting its innovative SIM.PLY thermoplastic line. This new machine produces premium tapes with precisely aligned, continuous fibres, which are opening up new applications in highly stressed, fibre-reinforced, lightweight structures. Dr. Jürgen Tröltzsch, Senior Manager of New Technologies at KARL MAYER Technische Textilien and his team had many conversations explaining exactly what these applications are. “Our first participation in the fair went extremely well. Interest in our existing machines and the new SIM.PLY line is high,” said Dr. Jürgen Tröltzsch on the third day of the fair. The visitors included many new contacts in the plastics sector, i.e. producers and processors of raw materials and semi-finished products, as well as manufacturers of finished plastic components, and the team discussed the next steps towards cooperating with them. Some of them will see the original SIM.PLY over the next few months. Processing trials are also being planned.

Several existing customers of KARL MAYER’s Warp Knitting Business Unit were also exploring new market opportunities in the composites sector. During these conversations, the textile machinery manufacturer was able to strengthen its reputation as an expert solutions supplier.

In addition to networking, the exhibition team effectively placed KARL MAYER Technische Textilien on the plastics market as an efficient player in the composites sector. “It is certainly worth us participating in the K trade fair. We have been able to position ourselves well, and have made contact with many people outside our familiar textile sector,” said Jochen Schmidt, the Managing Director of KARL MAYER Technische Textilien during the fair.

The company’s presence was even more important, since many representatives of competing technologies were also among the exhibitors. Turgay Turan, the new Manager of the Automotive Section at KARL MAYER Technische Textilien, emphasised this: “Many companies involved in plastics processing still do not appreciate the advantages of non-crimp fabrics for use in reinforcing composites. There is a huge potential here.”

The next stages will involve looking strategically at how this potential can be exploited effectively.