#Industry 4.0 / Digitalization

Covestro and Circularise partner in ISCC PLUS certification across value chains

Testing a blockchain system to complement ISCC PLUS

Circularise’s blockchain-based digital system was tested with the ISCC PLUS certification to make auditing of certified parties more efficient, and to strengthen the integrity of certified data. Participants used a public blockchain enabling authentication, accessibility, decentralization, and encryption of data verifying material flows and related sustainability attributes. "We are excited to bring our knowledge in supply chain traceability and data management to project partners to test a public decentralised blockchain with the ISCC PLUS certification," said Mesbah Sabur, Founder of Circularise.

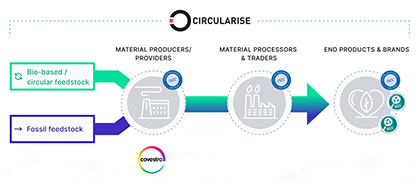

Material traceability and verification of data at individual sites and across the value chain are guaranteed by ISCC PLUS certification of each site of the operators, requiring site-specific audits, certification, and company-specific mass balance calculations to provide reassurance about the sustainable content. The data was uploaded to the Circularise software system to improve mass balance bookkeeping and reporting along the value chain through several companies.

"Certification will become more digital in the future. It will allow certification schemes to simplify the auditing process of supply chain actors and reduce the risk of mistakes. Companies will have an easier way to show compliance and adhere to auditing rules," says Jan Henke from ISCC. "We are excited to have tested Circularise’s traceability software on ISCC procedures."

Digitized ISCC certification for Covestro downstream customers

Covestro joined the ISCC pilot to understand how they can more efficiently communicate their sustainability information to their downstream partners.

"With other Circularise pilot projects, for example with Porsche, we were able to communicate raw sustainability data without a problem, but we had not yet addressed sustainability certifications. In the ISCC pilot we have shown now how we can easily attach certifications that can be digitally carried all the way through the value chain from Covestro to our downstream partners and finally to OEMs and beyond," explains John Fox from the Digital R&D area at Covestro. The company is seeing increasing demand from customers and partners for a digital certification system that can validate material sustainability claims via a system like ISCC.

Mass balancing is an emerging concept, not yet fully understood on the consumer side. So, in order to help ISCC and the entire mass balancing approach to reach out further down the value chain, the delivery of digital certified information through a simple and compatible system can give downstream partners an easier and more recognized tool to communicate and share sustainability attributes externally, all the way down to the consumer.