#Industry 4.0 / Digitalization

Introducing Smartex FACT: a digital textile factory in your pocket

Picture this: sipping your morning coffee while already knowing what happened in your factory overnight. Transform the way you manage your factory operations today. Say "no more" to the lack of digitalization and control over your production.

Manufacturers often struggle with inefficiencies, quality issues, and the need for manual inspections, which can lead to increased costs and decreased competitiveness. Smartex FACT steps in to address these challenges by providing automated performance insights into machine data, roll production statistics and quality. You can also personalize settings for quality control and even utilize a 'fast track' option for Grade A rolls (high-quality rolls that can go straight to your customer without any manual inspection). With data-driven decision-making at their fingertips, knitting manufacturers can now elevate factory operations, ensure consistent quality, boost overall efficiency, and outpace the ever-evolving competitive landscape of the textile industry.

Enough suspense, let’s dive right into Smartex FACT’s key features:

Automatic Roll Grading: with this feature, Smartex FACT enables you to set up your own Quality Standards to determine the automatic grading of knitted rolls based on the severity of detected defects. With a defined grading system in place, you can guarantee uniform quality standards throughout your production process, thanks to Smartex CORE’s AI-driven quality control. Typically, in the case of knitted fabric rolls, only about 10% undergo inspection.

But worry not – we've got you covered. With Smartex, every roll will undergo automatic inspection and grading, with Grade-A rolls receiving a Fast Track label - that can be printed and applied to rolls with Smartex LOOP - so you always know where to focus your attention.

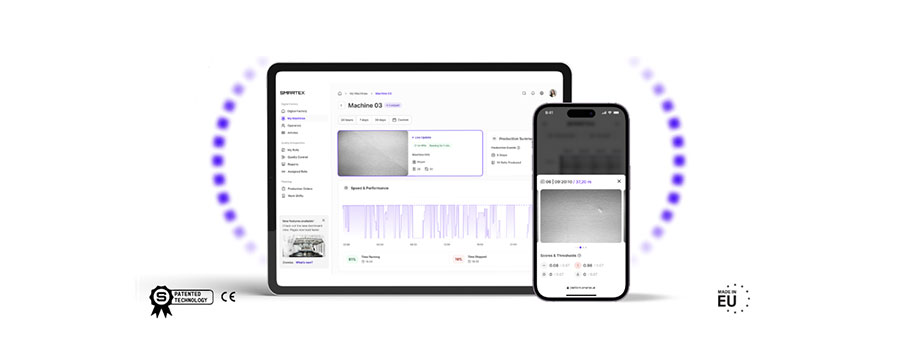

With our Digital Factory Page, users gain a complete overview of their factory including the number of machines currently running and rolls produced on that day.

Our My Machines Page provides in-depth, precise data about the performance of every machine powered with Smartex within your factory, including RPM speed and operating time. You'll have the tools to comprehensively assess each machine's performance empowering you to fine-tune machine operations, boosting both quality and productivity across your factory.

On top of the importance of speed and performance, Smartex places a high priority on quality. Our My Rolls Page grants clients access to a whole month of their production history. Here, you can zoom into each roll's production details to assess quality and even review where defects were detected in the digital roll map.

Last but certainly not least, stay in the know with Real-time Notifications tailored to your priorities. Whether it's machines operating at a lower RPM, excessive machine downtime, or the identification of poor-quality rolls, you'll receive timely updates. As a result, you can make data-informed decisions around increasing RPM speed, inspecting lower-quality rolls, and responding to other machine-related issues.

Gilberto Loureiro, Co-founder and CEO of Smartex.ai, stated, "Our new product takes manufacturing and quality control to the next level. With Smartex FACT, users will be able to know when rolls don’t meet the requested quality or when production issues arise. And with the platform being easily accessible via desktop or any smartphone, it is basically your textile factory in your pocket."

As a pioneering and award-winning company, Smartex has consistently been at the forefront of transforming textile factories through hardware-based software solutions and the creation of essential tools for the Modern Textile Factory. Today, we take immense pride in unveiling our latest innovation to the world: Smartex FACT. This cutting-edge platform opens the door to undeniable data for factory operations, equipping clients to fortify their businesses for the future. With the power of data-driven decision-making, enhanced efficiency, and elevated quality, Smartex FACT is set to redefine the knitting textile industry landscape.

Don't wait, join the hundreds of leading factories already using AI in their production today with Smartex FACT (now available in English, Portuguese, and Turkish with more languages coming soon!). Visit www.smartex.ai to learn more or contact sales@smartex.ai to get started.