India ITME 2012

AUTEFA Solutions at INDIA ITME 2012

AUTEFA Solutions is a group of three machine manufacturers and represents European companies with a long tradition and a history of years of successful participation in the market. These are the AUTEFA company in Friedberg, the Austrian sister company Fehrer in Linz, and the Italian companies F.O.R./OCTIR in Biella.

With the company locations in Friedberg (Germany), Linz (Austria) and Biella (Italy), AUTEFA Solutions is positioned at the heart of Europe. From these locations, machinery and systems are exported to customers around the world. The group also has branches in the USA and China.

AUTEFA Solutions delivers complete lines as well as individual machines for nonwovens manufacturing. Different applications are the production of artificial leather, filter products and paper-machine felts to automotive felts, geotextiles, floor coverings, felts for insulation and nonwovens for the hygiene industry. AUTEFA Solutions machinery could be used for the production of glass-fibre or carbon-fibre reinforced plastics. These nonwovens are used in automotive construction, shipbuilding, the aircraft industry or wind turbines.

AUTEFA Solutions scope of products includes preparation machinery, carding machines, as well as random carding machines (Airlay cards), needle looms and crosslappers.

Visitors will find information about the newest developments and technical experts are ready for discussions.

The growing Indian Nonwovens industry needs high quality machinery to deliver best quality. High quality machinery from AUTEFA Solutions is equippet with highly efficient and powerful drive systems. The company has continuously optimised the air control of the individual machines, saving energy through the use of modern engines and a low load on the filter units.

In order to ensure sustainability and efficiency production processes AUTEFA Solutions has intelligent processes to save the use of material; when surplus material is not produced, the energy that would have been used in production is no longer used.

AUTEFA Soltuions machines have following advantages:[pStylus needle loom ]

The Stylus needle loom is equipped with the innovative Variliptic drive system. Purely vertical and elliptic motion sequences are implemented with just one drive by the corresponding offset settings in the two eccentric gears which make up the drive system. The Variliptic drive system enables high production speeds while also ensuring a gentle needling of the nonwoven fabric. This is particularly important during the first process step, the preneedling. The Variliptic drive system optimises the surface of the nonwoven fabric, while also protecting fibres and minimising on the needles wear. Thanks to its modular design, the flexible Stylus needle loom can be used for all applications. The needle bars can be changed quickly so that extended downtimes are avoided. The i-point simulation program contributes to the improvement of surface properties, tenacity and product characteristics through the computer-based generation of customer-specific or product-specific needle patterns. At the same time, i-point is used for the computerised development of new products. This avoids long series of trials and production downtimes. The Stylus needle loom represents the next generation of successful Fehrer needle looms. The Stylus is available in machine widths from 2 m to 8.5 m and can be used in all areas of nonwoven production.

Airlay Card K 12 DIRECT

The Airlay Card K 12 DIRECT utilises an aerodynamic principle which results in three dimensional fibre orientation and total randomisation. Total fibre randomisation enables isotropic web strength. The aerodynamic principle results in maximum product quality, economical production and reliability from a single source. The Airlay card K 12 DIRECT is suitable for the production of top quality webs in a weight range of 80 to 6,000 g/m².

Due to the direct transfer from the chute feed to the Airlay Card without an additional opener, the fibres are gently opened up and formed into the nonwoven fabric. The Airlay Card K 12 DIRECT is a short and compact machine that offers the following advantages:

Reduction of filter size and exhaust air

- Lower energy consumption

- Reduced space requirements

- Gentle fibre treatment

AUTEFA Solutions Airlay Card K 12 can be used to process all kinds of man-made fibres, viscose, cotton, cotton blend, jute, flax, hemp, bamboo, coconut and ramie as well as regenerated waste. The units are short and gentle on fibres. The renewable, naturel fibres are used to create voluminous, 3-dimensional nonwoven felts that are then processed into composites, for example with propylenes or polyester in the top and bottom layer.

Pic 2: AUTEFA Solutions: Airlay card K 12 DIRECT

Crosslapper Topliner profile controlled by WebMax

Weight accuracy in the bonded lapped web is the most requested quality feature for a modern nonwoven installation. WebMax together with the Crosslapper Topliner produces a counterweight profile to the 'Smile' profile on the layering belt of the Crosslapper during carded web production.

With the WebMax, the carded web weight is altered at the Crosslapper infeed and, via the layering carriage control, the carded web is deposited on the layering belt in such a way that the lapped web weight is controllably lighter in the edge areas than in the centre areas. This concave weight profile therefore compensates the weight changes resulting from material shrinkage and ensures the highest possible weight evenness in the final product.

By improving the lapped web profile, WebMax also provides a reasonable reduction of material consumption.

The precise cooperation between web infeed and web lapping ensures exact profiling of the carded web with a straight edged layering pattern.

Crosslappers Topliner from AUTEFA Solutions stand out thanks to their high production speeds and the high quality webs. When the Crosslapper is used in combination with the WebMax control system, a saving of 20% can be made on material. This is achieved through the reduction of fibre usage via weight reduction at the edge areas of the nonwoven fabric.

The ‘Smile’ effect – the increased thickness of the nonwoven fabric at the edge areas – is achieved by means of drafts and an uneven material shrinkage during the bonding of the nonwoven fabric. The WebMax also comes into play here, compressing the carded web and periodically drafting of the web taking into account the Crosslapper width. The precise placement of the drafted zones on the conveyor belt is particularly important as it enables the weight profile to be created in line with the ‘Smile’ effect.

The Injection card

One of the most interesting markets for non woven, that had a real fast and strong grow in the last years, is the Spunlace, that is the nonwovens bonded by water jet.

The products are mainly used in the medical and hygienic field but also in the technical applications , and have the big advantage, in front of a traditional needle punched products, to reach the same specific characteristics with a lower quantity of fibres, with a better “hand”, but moreover, with a very high production speed.

For this special market, but not only limited to this, Autef Solutions has developed since 1995 a special card, the Injection card, that is the only real new concept in carding of the last century and proved successful from the very beginning.

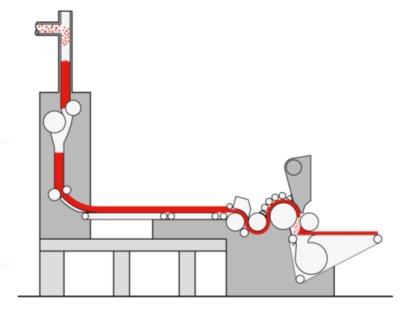

Pic 3: Autefa Solutions: Injection Card

The Injection Card uses the aerodynamic principle to gently treat fibres when opening them and in parallel, the new carding concept avails itself of some of the advantages of the cotton card and of some of those of the traditional card, with workers and strippers. The carding effect is improved, the recycling of fibres is totally negligible, and the isotropy of the product is increased; all the above advantages make the Injection Card the most suitable card for high-production Spunlace lines.

The new generation of Injection Card, called Injection Card PLUS, has improved performance, enables more easy maintenance and optimised reliability.