#ITMA 2019

Kornit Digital brings its latest innovative and sustainable solutions for industrial digital textile printing to ITMA 2019

- Commercial availability of the new Kornit Presto, the world’s only industrial single-step solution for direct-to-fabric printing

- Official launch of the new Kornit Konnect, a software analytics platform that provides data-driven insights for better business management and results

- Showcasing collaboration with Adidas with live production on the recently announced Kornit Atlas and Avalanche Poly Pro systems

Innovation for the modern supply chain

Driven by mega-trends, brands and retailers seek to connect with consumers, and are adapting their supply chains accordingly, paving the way to digital textile printing. The mega-trends driving for change are: personal expression in the social media era; an e-commerce environment of endless choices; and a strong sustainability imperative.

Kornit’s mission is to be the vendor of choice for apparel and home décor industry players, and to accelerate the supply chain optimization. Ronen Samuel, CEO, Kornit Digital, commented, “We work closely with the world’s leading brands to support their business innovation strategies. Kornit's technologies enable unlimited design creativity, faster turnaround times and sustainable production.”

Fastest and most sustainable way to print on textile

The new Kornit Presto addresses the supply chain challenge head on. It is the world’s only industrial single-step solution for direct-to-fabric printing. The system is perfectly suited for the home décor and fashion markets. It eliminates the need for pre and post treatment of fabric and allows for high-quality printing on an extraordinarily broad variety of fabric types. The Kornit Presto solution uses the 100% water-free patented NeoPigmentTM process, and is the shortest process from file to finished product, making it the most environmentally friendly solution available for direct-to-fabric textile printing today.

A vision of digital eco-system for real-time production and business insights

Kornit Konnect is a cloud-based software analytics platform that enables businesses to monitor production, analyse insights and manage their fleet, to eliminate blind spots. It includes a fleet management dashboard, data-driven benchmarks, actual production costs, and cost structures per job, making it easy for businesses to learn more, react faster and perform better.

“While businesses need to deliver high quality, faster than ever, to maintain customer loyalty, they are also challenged to maximize their efficiency and productivity,” said Omer Kulka, VP Marketing & Product Strategy at Kornit Digital. “Konnect empowers these businesses to make better-informed production decisions, with greater visibility and control over their operations. Kornit plans to enhance this cloud-based platform frequently with new features as part of our innovation strategy.”

Showcase of successful solutions

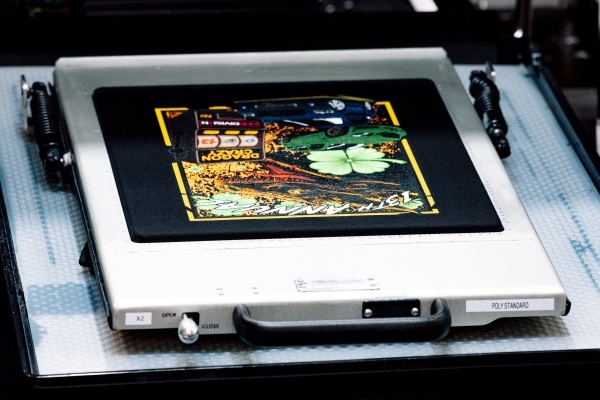

Also on show in the booth are the Kornit Atlas and the Avalanche Poly Pro systems that were introduced earlier this year. Following dozens of installations worldwide and successful ramp-up at multiple customer sites, hundreds of thousands of garments have already been produced. Kornit will perform live printing of Adidas products on these two systems at ITMA. The Adidas mission is to be the best sports company in the world and one of their three key strategic choices is an Open Source strategy. Adidas is collaborating with Kornit to support their direct-to-garment innovation strategy, with Kornit as a key partner in digital embellishment. Adidas has recently invested in the Kornit Atlas and Avalanche Poly Pro solutions and is looking to expand its digital embellishment capabilities further.

The Kornit booth at ITMA (Hall 3 A211) is a gathering of world class experts: application and customer empowerment specialists as well as business consultants. Don’t miss this singular opportunity to meet the people who are focused on the innovation that allows leading brands to better connect with their customers and to adapt to the rapid changes in consumer preferences.