#ITMA 2019

“Weave by Wire”: Why the digital age began much earlier for weaving machine manufacturers like DORNIER

DORNIER Air-Jet Weaving Machine A1, Type AWS 6/J G with a nominal width of 240 cm Artikel: Outdoor clothing fabrics (OPW)

(Image: “Outdoor”; Source: DORNIER)

For most industries, automation is a relatively new trend which presents them with enormous challenges. But for weaving machine manufacturers like DORNIER, the issue has been an ever-present consideration for many decades. A little historical context: Back in 1805 in Lyon, France, at that time the center of the world’s silk weaving industry, weaver’s son Joseph-Marie Jacquard took a piece of card and invented a weaving loom that was controlled by perforation patterns – and at a stroke he revolutionized fabric production. From that point on, perforated cards contained and communicated all the defining information for the patterns of fabrics for upholstery, tapestries and clothing.

And it was not just fabric manufacturing itself which underwent a complete transformation: The loom as “programmable” machine was a fundamental element for today’s automation. Well over a century later, the punched card spread was intro- duced into data processing, assisted by an American named Herman Hollerith. From there it made its way to binary computer programming. Finally, in 1924 the company founded by Hollerith paved the way for a business which in those days was called “International Business Machines Corporation”, but which is now known exclusively by its short form: IBM.

Future-oriented weaving: One-piece outdoor trousers

At the ITMA international textile and garment technology exhibition, the precursor to digital technology as invented by Jacquard will again play a forward-looking part. For example, the stand of machinebuilder Sta?ubli will feature an air-jet weaving machine from DORNIER which will be used to produce a pair of outdoor trousers from a single piece. Undoubtedly, weaving is a very familiar technique for users of outdoor apparel, because the two-thread system of weft and filling threads lends the requisite flexibility and tear resistance to equipment which is expected to withstand harsh weather conditions. But outdoor trousers as “One Piece Woven” (OPW) represents a world first. “The question is: How can the manufacture of outdoor clothing be trans- ferred from two to three dimensions?”, says Volker Janke, Product Applications Manager for air-jet weaving machines.

A large outdoor apparel provider approached a fabric manufacturer – one of DORNIER’s customers – with a request to develop a more sustainable, more flexible process for manufacturing outdoor products. It is not inconceivable that this was also prompted by emerging (online) purchasing patterns, because keywords such as Fashion on Demand and Pay per Piece show that consumers and their rapidly changing needs, demands and individual wishes are seen increasingly as the starting point for production. But this means that production must be adapted – that is to say it must become more agile. “The OPW outdoor trousers are an example of future-oriented fabric production”, says Janke. The objective is to be able to offer a product which is “tailored” precisely to the customer in terms of design, pattern and wearability, which is manufactures at the cost of less material, energy and waste. Janke has no doubt: “The road from two-dimensional to 3D weaving offers an entirely new dimension in manufacturing flexibility”.

Direct line 4.0: The new myDoX® customer portal

DORNIER will also present its new myDoX® customer portal publicly for the first time in Barcelona. It completes and expands our personal technical DORNIER service and the weaving machine panel ErgoWeave® with integrated Ethernet interface. “Log on and get to work immediately”, says Florian Stro?ßenreuther, Head of Training and Documentation. The system is based on HTML5 and ultramodern database technology (powered by SAP HANA). According to Stro?ßenreuther, it does not need any plug-ins or extra programs and can be operated with equal ease from a PC, smartphone, tablet or weaving machine control panel.

Besides serving as the 24/7 online shop (DoXPOS – Parts Order System) for original parts for all machine generations, an overview of orders (including display of processing progress), production and machine data and the enhanced DoXWeave software for the networking of weaving machines, myDoX® is also the direct line 4.0 to experts and information from the house of DORNIER. “It is the way for our customers all over the world to receive support they want at the highest possible technical level for their fabric production at all times”, Stro?ßenreuther concludes.

Unsurpassed terry weaving with DORNIER

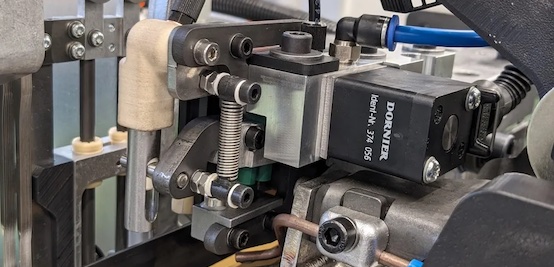

Visitors to the ITMA exhibition will also find a DORNIER weaving machine at the stand of machine builder Bonas, this time a terry weaving machine. Also combined with a Jacquard machine, it weaves three towels simultaneously over a width of 3.40 meters with supreme precision and loop quality. The typical DORNIER control system and flexible drives allow pile heights to be adjusted individually; and time-consuming manual adjustments are reduced thanks to automated speed changes, when changing from the pile to the border, for example. At the same time, electronic pressure control for the relay nozzles enables different pressures to be selected and programmed easily on the terry weaving machine according to design specifications. Other technology features on the terry air-jet weaving machine include the patented “Soft-Beat-up” for gentle terry beat-up to form the best possible pile, free access to warp stop motion positioning weight-reduced whip roll for even warp tension.