#ITMA 2019

Simpler and smarter with Monforts at ITMA 2019

The data can be easily accessed using the new Monforts Smart Support and Smart Check apps for an instantaneous status overview.

All specifications relating to machine performance and the production process can be mapped, to enable vastly simplified and targeted analysis for controlled planning and production. Insights harnessed from such analysis can be used to optimise the actual production process.

At the same time, potential sources of error can be anticipated and eliminated, enabling improved machine availability while considerably minimising downtime.

Parts prediction

In addition, the digital twin system provides information on the individual wear parts of a system, such as, for example, converters or gears.

“Operators and mill managers are informed by Smart Check sensors when maintenance or the replacement of key components will be required, well ahead of time,” explains Monforts Vice President Klaus A. Heinrichs. “Direct access to the integrated Monforts webshop allows users to instantly order such parts when they are needed, virtually preventing machine downtime.”

On request, Monforts can also virtually monitor machine performance and pro-actively alert customers to the need for preventative action. In such cases, however, data is only ever called from the cloud by Monforts when customers have given their full consent, in the interests of data security.

Data from Smart Check, for example, can even be used to analyse a system’s energy requirements, allowing machine operation to be optimised by tailoring production runs to the peaks and troughs of electricity costs.

Remote maintenance assistance

At present with Smart Support, customers can also contact Monforts service via smartphone or tablet, in order to access support on site via a remote visual link. Monforts service specialists can point out individual system parts on the customer’s smartphone and assist them in troubleshooting. Documents such as machine documentation can also be shown in real-time via white-board over a smartphone, tablet or office PC.

“The Monforts digital twin system and apps are being made available for all of our machine ranges going forward and will make the operations of our customers considerably smarter, and at the same time, simpler,” Mr Heinrichs concludes.

Further benefits and savings with the new Monforts MonforClean

Furthermore, Monforts will be presenting an energy-optimised new version of its industry-leading Montex stenter for the first time.

With the introduction of the new MonforClean exhaust air treatment system and other unique process innovations, Monforts has been able to further reduce the energy consumption of Montex stenters by a further 13%. Exhaust air treatment on stenter frames has posed particular challenges over the years, since the air can contain significant amounts of oil, fibre and even wax particles that may see emissions limits being reached in the processing of certain fabrics, depending on the legal specifications.

In addressing this issue, Monforts is now incorporating the MonforClean module into the stenter frame, so there is no additional space requirement. At the same time, the costs for laborious secondary installations and the piping of the exhaust air treatment components, as well as supporting structures are eliminated due to the machine configuration.

The waste heat from the drying process is used to pre-heat the drying air, resulting in a radical reduction in the conventional heat supply required compared to gas and thermal oil heating. The further integration of an automatic exhaust air filter washing system automatically cleans the module elements, ensuring the consistent efficiency of both the filter and heat recovery modules.

The modular MonforClean system is also available in different expansion stages and automates the heat recovery and exhaust air treatment, while eliminating odours and ensuring the exhaust air is highly purified before escaping into the atmosphere.

This allows finishing mills to always be on the safe side, ensuring growing future demands in respect of heat recovery, exhaust air cleaning and odour elimination can always be met when required.

Bionics

Another challenge on a finishing line is exposure of the fabrics to ambient air at the stenter’s entrance and exit, which can also lead to a loss of energy.

A new innovation here is in the form of advanced slot sealings based on a patented new flexible material in a configuration that draws on bionics – specifically the way the fins of fish will automatically steer a passage through water with endless, barely discernible movements.

This material serves to hermetically seal the stenter frame at the infeed and outfeed while constantly adjusting to the profile of the different fabrics being cured and ensuring an absolute minimum of cold air is drawn in and only marginal warmth can escape.

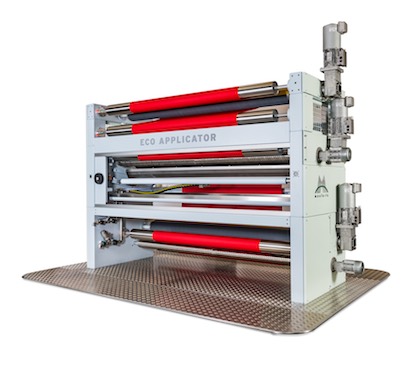

Eco Applicator

Additional energy can be saved by installing a Monforts Eco Applicator in front of a Montex stenter, which can significantly minimise the application of finishing formulations required for specific treatments compared to a padder/foulard, resulting in a big reduction in the energy required for subsequent drying in the stenter and reducing the amount of residual liquor when draining the trough after the finishing process.

“The latest energy-optimised Monforts stenter frame – especially combined with a downstream Eco Applicator – sets new benchmarks in terms of energy efficiency and helps conserve resources,” says Klaus Heinrichs, Monforts Vice-President. “Setting the initial moisture content requirement for a specific process, before drying to a minimum value with an automated process, helps reduce heat evaporation and consequently, energy consumption.

“In addition, the hermetic sealing of the stenter frame prevents the loss of heated air as well as the ingress of excessive cold air – which has to be heated back up. The MonforClean module automates the heat recovery and exhaust air treatment processes, while eliminating odours. As a result, the maximum possible energy savings no longer depend on the machine operator, but are instead harnessed in automatic operation. The MonforClean’s modular design can be adapted individually to the needs of the customer. Options include the HR heat recovery module only, the HR plus the EAC (exhaust air cleaning) module or the HR, EAC and a UV module for elimination of odours. The system prevents visible smoke from coming out of the stack of a dryer.

“In total, the latest Monforts energy-optimised stenter frame will cut energy consumption by up to forty per cent compared to a conventional stenter equipped with no heat recovery or energy optimisation measures. We invite all existing and new customers who are looking to conserve resources and save long-term on costs in the energy-intensive drying process to come and talk with us at ITMA 2019. Thanks to a significant reduction in energy costs, they will discover that the investment costs in new Monforts installations pay off surprisingly quickly.”